Automatic thermal laminating machines are essential tools for protecting and enhancing printed materials in various industries and businesses. To ensure optimal performance and longevity of your laminating machine, regular maintenance and proper care are essential. In this comprehensive guide, we'll explore the key steps and best practices for maintaining and caring for your automatic thermal laminating machine.

Regular cleaning is crucial to prevent the buildup of dust, debris, and adhesive residue that can affect the performance of your laminating machine. Here's how to clean your machine effectively:

• Use a soft, lint-free cloth to wipe down the exterior surfaces of the machine, including the control panel, rollers, and feed tray.

• Remove any adhesive residue or debris from the rollers using a roller cleaning pad or adhesive remover. Be sure to follow the manufacturer's instructions for cleaning products and techniques.

• Check the heating elements for any buildup or discoloration and gently clean them with a soft brush or cloth if necessary.

• Clean the cooling fans and vents to ensure proper ventilation and prevent overheating.

Proper lubrication is essential to keep the moving parts of your laminating machine running smoothly and prevent premature wear and tear. Follow these guidelines for lubricating your machine:

• Use a high-quality lubricant recommended by the manufacturer for lubricating the rollers, gears, and other moving parts.

• Apply the lubricant sparingly and evenly to avoid excess buildup, which can attract dust and debris.

• Wipe away any excess lubricant with a clean cloth to prevent it from transferring to laminating materials.

Regular inspection of consumable parts such as rollers, heating elements, and cutting blades is essential to ensure smooth operation and consistent results. Here's what to look for during your inspections:

• Check the condition of the rollers for signs of wear, scratches, or uneven surfaces. Replace worn or damaged rollers promptly to prevent quality issues and paper jams.

• Inspect the heating elements for any damage or malfunction, such as uneven heating or discoloration. Replace faulty heating elements to maintain consistent lamination quality.

• Check the cutting blades for sharpness and alignment. Dull or misaligned blades can result in uneven cuts and poor finishing. Sharpen or replace the blades as needed.

Calibration is essential to ensure accurate operation and consistent results from your laminating machine. Follow these steps to calibrate your machine:

• Refer to the manufacturer's instructions for specific calibration procedures for your model of laminating machine.

• Use a calibration tool or test materials provided by the manufacturer to verify the accuracy of temperature settings, pressure settings, and other parameters.

• Make any necessary adjustments or corrections to ensure that the machine is operating within the specified tolerances.

Proper storage is essential to protect your laminating machine from damage and prolong its lifespan. Follow these guidelines for storing your machine:

• Store the machine in a clean, dry, and well-ventilated environment away from direct sunlight, moisture, and extreme temperatures.

• Cover the machine with a dust cover or protective sheet when not in use to prevent dust and debris from accumulating.

• Follow the manufacturer's recommendations for storing the machine, including any specific instructions for disassembly or preparation for long-term storage.

In addition to cleaning and inspecting the machine, it's essential to perform regular maintenance checks to ensure that all components are functioning correctly. Here are some additional maintenance tasks to consider:

• Check the alignment of rollers and guides to ensure smooth paper feeding and consistent lamination.

• Inspect electrical connections and wiring for signs of wear, damage, or loose connections. Tighten or replace any damaged components as needed.

• Test the machine's safety features, such as emergency stop buttons and overload protection mechanisms, to ensure they are working correctly.

Regular maintenance and proper care are essential for ensuring the optimal performance and longevity of your automatic thermal laminating machine. By following the guidelines outlined in this guide, you can keep your machine running smoothly, minimize downtime, and prolong its lifespan. Remember to refer to the manufacturer's instructions and recommendations for specific maintenance procedures and intervals. With proper maintenance and care, your laminating machine will continue to deliver high-quality results for years to come.

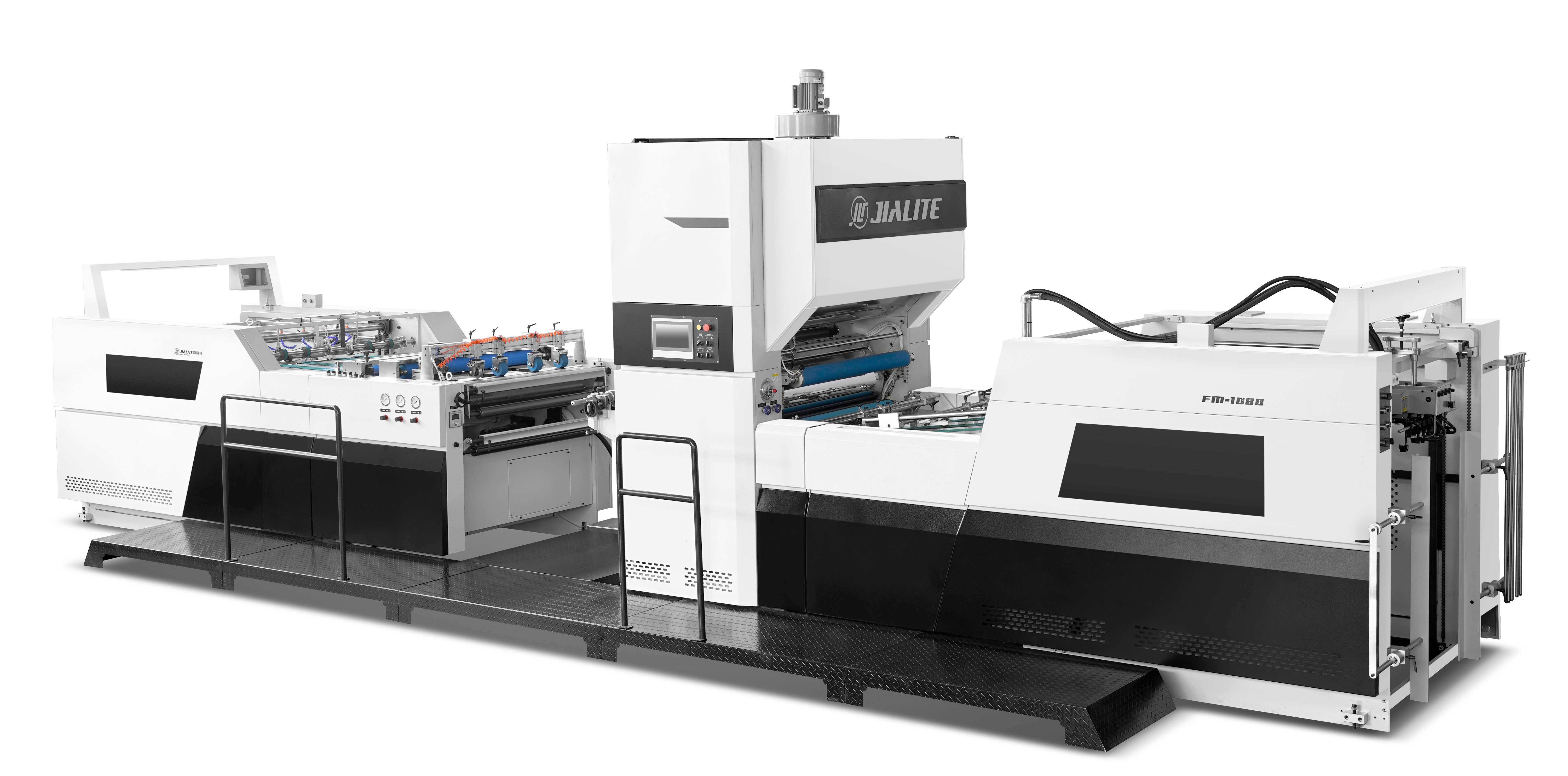

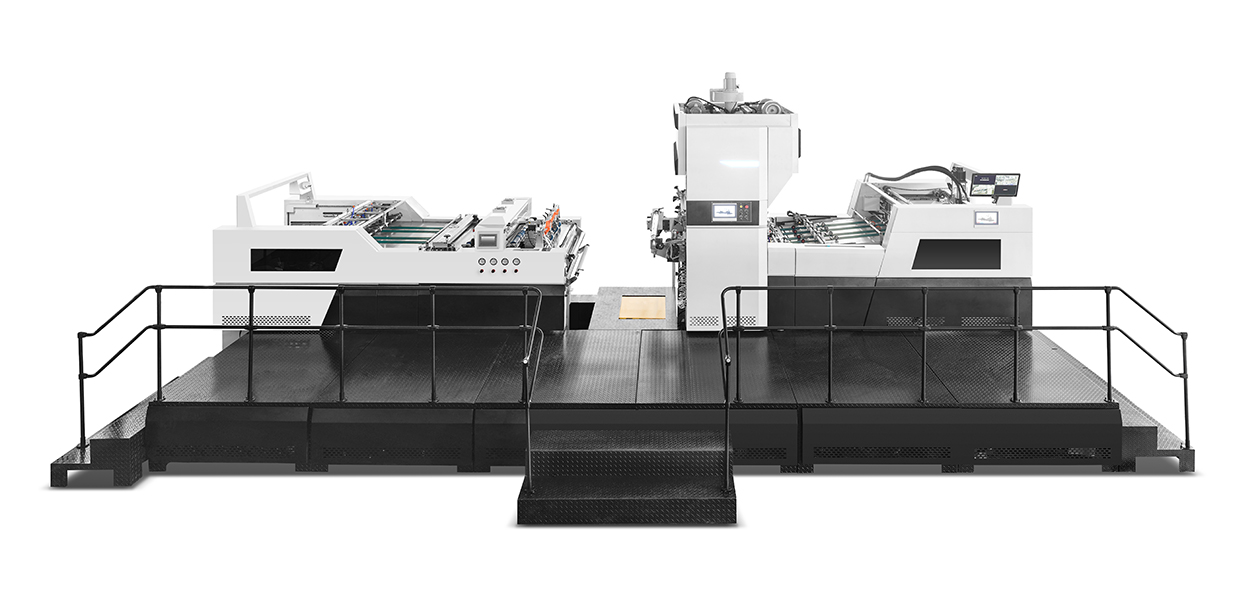

Why Choose JIALITE for Your Coating Machines?

2024-03-23Exploring Window Film Laminating Technology: Adding Convenience and Appeal to Your Products!

2024-04-11Advantages and Product Protection Effects Analysis of UV Oil Coating Technology

2024-04-30EXPOGRÁFICA 2024 --12th-15th November Meet you in Mexico

2024-11-05Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

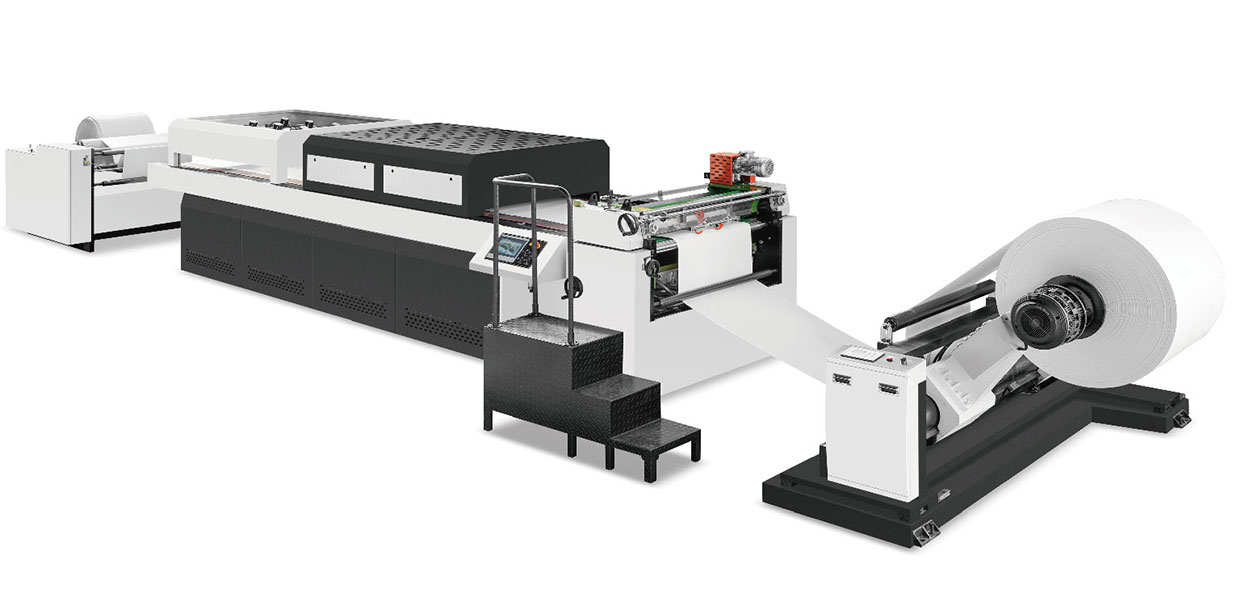

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01

23 Mar, 2024

READ MORE

JIALITE is a trusted global leader in high-precision coating and laminating machines, offering cutting-edge solutions for printing, packaging, and paper processing industries. With decades of expertise, customized designs, and reliable support, JIALITE is your ideal partner for boosting production efficiency and quality.

11 Apr, 2024

READ MORE

Window film laminating technology not only provides an attractive display for products but also enhances consumer shopping experience and convenience. As an advanced packaging technique, it will continue to play a significant role in various industries, offering new possibilities and creativity in product packaging.

30 Apr, 2024

READ MORE

Explore the advantages of UV oil coating technology and automatic UV coating machines. Learn how these innovative solutions enhance product protection, durability, and production efficiency for businesses across various industries.

05 Nov, 2024

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING