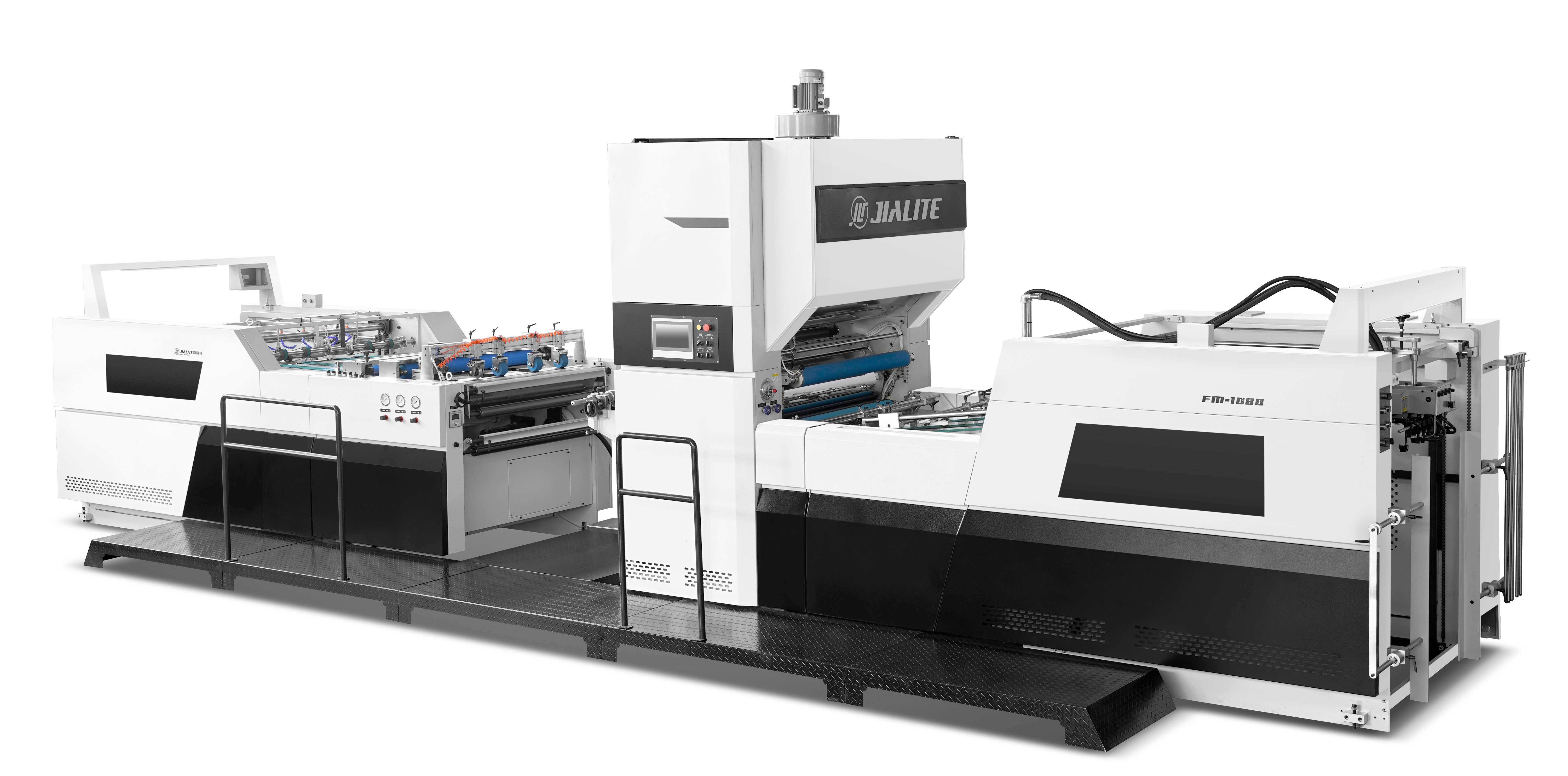

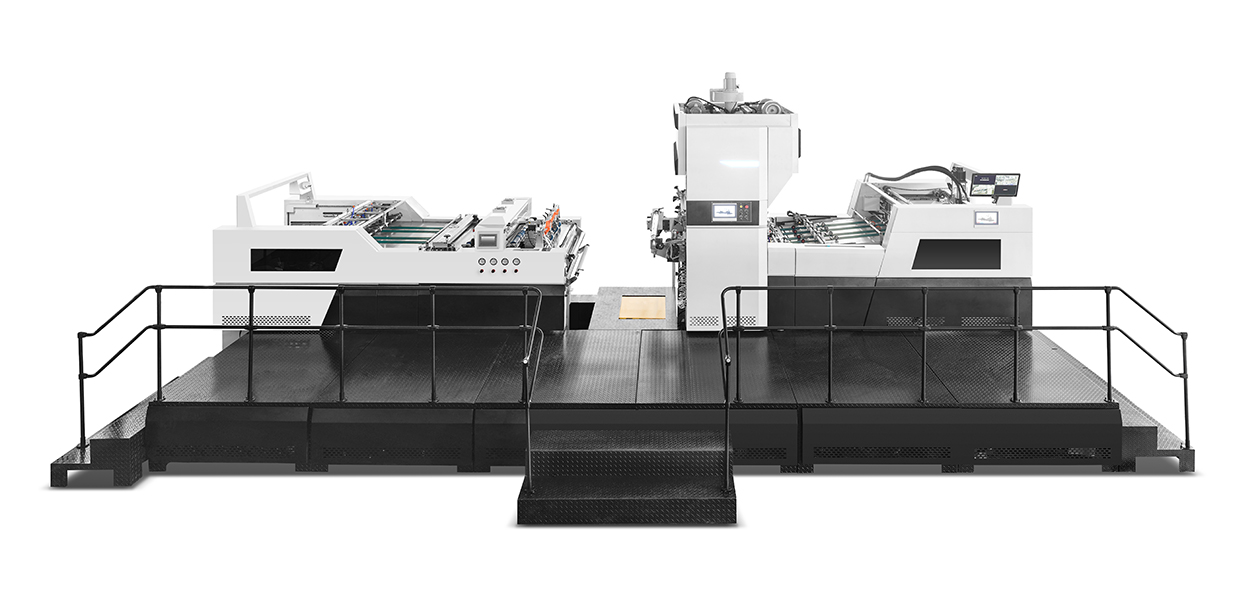

The 2-in-1 Automatic Vertical Laminating Machine is revolutionizing the production efficiency in various industries. With its advanced technology and capabilities, this machine offers a range of benefits that maximize productivity and streamline the laminating process.

In order to understand the significance of this machine, it is important to first grasp the concept of production efficiency. Production efficiency refers to the ability to optimize the use of resources, minimize waste, and maximize output within a given time frame. It is a key factor in determining the success and profitability of any manufacturing process.

The 2-in-1 Automatic Vertical Laminating Machine stands out as a game-changer in the industry due to its unique functionalities and features. It combines the functions of two machines - laminating and cutting - into a single, efficient unit. This eliminates the need for separate machines and enhances production efficiency by reducing turnaround time and eliminating process duplication.

By utilizing the vertical laminating technique, this machine offers several advantages over traditional laminating methods. Its ability to handle multiple sheets simultaneously and perform high-speed laminating increases productivity and saves valuable time. Additionally, the machine's user-friendly interface and automated functions contribute to its efficiency and ease of use.

In the following sections, we will delve deeper into the functionalities, key features, applications in various industries, maintenance tips, and troubleshooting techniques associated with the 2-in-1 Automatic Vertical Laminating Machine. Overall, this machine has a significant impact on production efficiency and offers promising developments in laminating technology for the future.

Maximizing production efficiency is a crucial factor in any manufacturing process as it directly impacts the success and profitability of a business. It involves optimizing resource utilization, minimizing waste, and maximizing output within a given timeframe. By streamlining operations and improving productivity, businesses can reduce costs and increase their competitive edge in the market.

The 2-in-1 Automatic Vertical Laminating Machine is a game-changer when it comes to maximizing production efficiency. Its advanced technology and capabilities offer a range of benefits that enhance productivity and streamline the laminating process.

This machine combines the functions of two separate machines – laminating and cutting – into a single, efficient unit. By eliminating the need for separate machines, it reduces turnaround time and eliminates process duplication, thus maximizing productivity.

The vertical laminating technique used by this machine further contributes to production efficiency. Its ability to handle multiple sheets simultaneously and perform high-speed laminating saves valuable time. The machine's user-friendly interface and automated functions make it easy to operate, enhancing efficiency and reducing the chances of errors.

In conclusion, the 2-in-1 Automatic Vertical Laminating Machine has a significant impact on production efficiency. Its capabilities, combined with the vertical laminating technique, offer promising developments in laminating technology for the future. By investing in this machine, businesses can maximize productivity, reduce costs, and stay ahead in a competitive market.

The 2-in-1 Automatic Vertical Laminating Machine offers a range of benefits that contribute to maximizing production efficiency. By combining the functionalities of two separate machines, laminating and cutting, into a single unit, this machine saves valuable time and eliminates the need for process duplication. This streamlined operation reduces turnaround time and increases productivity.

The vertical laminating technique used by this machine further enhances efficiency. Its ability to handle multiple sheets simultaneously and perform high-speed laminating significantly reduces the time required for the laminating process. This not only maximizes output but also ensures a consistent and high-quality final product.

The machine's user-friendly interface and automated functions make it easy to operate, even for inexperienced users. This reduces the chances of errors and enhances efficiency. Additionally, the machine's quick setup and minimal maintenance requirements further contribute to increased productivity and reduced downtime.

In summary, the 2-in-1 Automatic Vertical Laminating Machine offers the following benefits:

1. Streamlined operations and reduced turnaround time.

2. Elimination of process duplication and increased productivity.

3. High-speed laminating and handling of multiple sheets simultaneously.

4. User-friendly interface and automated functions for enhanced efficiency.

5. Quick setup and minimal maintenance requirements.

The 2-in-1 Automatic Vertical Laminating Machine incorporates advanced technology to optimize production efficiency. This cutting-edge machine combines the functionalities of laminating and cutting into a single unit, eliminating the need for separate machines and reducing process duplication.

The key features of this technology include a user-friendly interface and automated functions that simplify operation. The machine is designed to be easily operated, even by inexperienced users, minimizing the chances of errors and maximizing efficiency. Additionally, the quick setup and minimal maintenance requirements contribute to reduced downtime and increased productivity.

The vertical laminating technique employed by this machine further enhances production efficiency. It has the capability to handle multiple sheets simultaneously and perform high-speed laminating, significantly reducing the overall processing time. This not only maximizes output but also ensures consistent and high-quality results.

By understanding the technology behind the 2-in-1 Automatic Vertical Laminating Machine, businesses can harness its capabilities to eliminate inefficiencies and optimize their production processes. This innovative technology paves the way for improved productivity, reduced turnaround time, and the delivery of superior laminated products.

The 2-in-1 Automatic Vertical Laminating Machine offers a range of functionalities that contribute to its efficient operation. With the ability to perform both laminating and cutting functions, this machine eliminates the need for separate equipment and streamlines the production process.

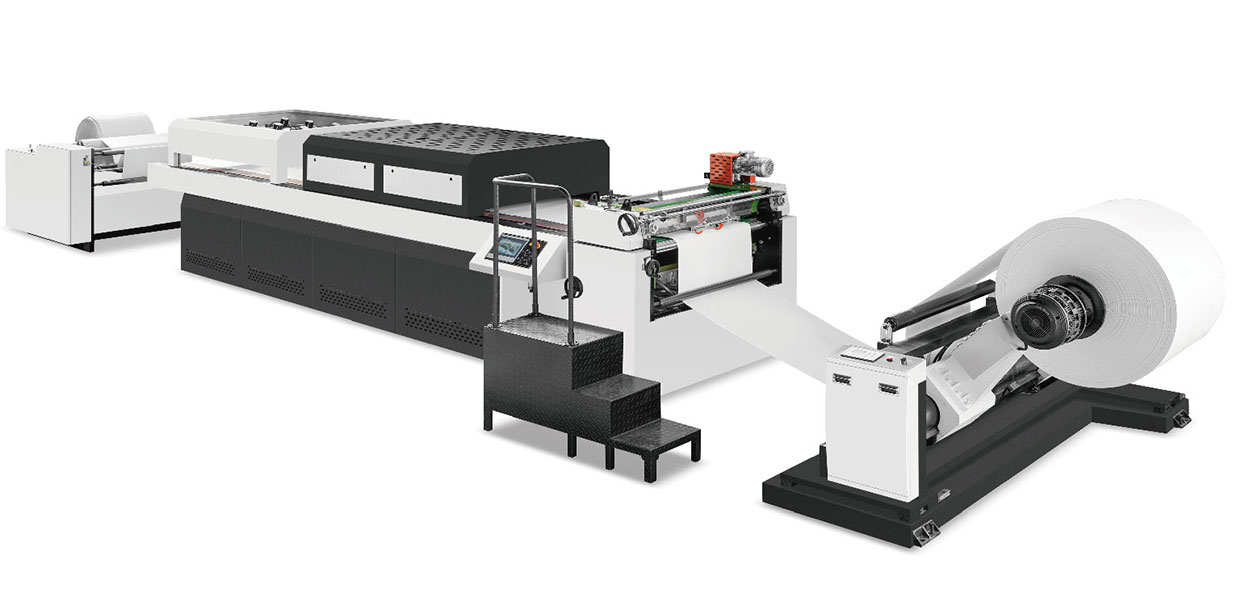

The laminating functionality of the machine allows for the application of a protective film onto various materials, such as paper, cardboard, or plastic, ensuring durability and enhancing their visual appeal. This protective layer acts as a barrier against moisture, dirt, and wear and tear, extending the lifespan of the laminated products.

In addition to laminating, the machine also incorporates cutting capabilities, enabling the precise trimming of laminated sheets to the desired size and shape. This eliminates the need for manual cutting, saving time and ensuring uniformity in the finished products.

Furthermore, the 2-in-1 Automatic Vertical Laminating Machine offers automated functions to simplify operation. The user-friendly interface allows for easy adjustment of laminating and cutting parameters, ensuring precise results. The machine is also equipped with sensors and detectors to detect errors, reduce waste, and prevent damage to the materials, further increasing efficiency.

Overall, the functionalities of the 2-in-1 Automatic Vertical Laminating Machine enhance production efficiency by streamlining processes, reducing manual labor, and ensuring consistent and high-quality laminated products.

The 2-in-1 Automatic Vertical Laminating Machine incorporates key features that significantly enhance production efficiency. These features are designed to streamline operations, reduce manual labor, and ensure consistent results.

One of the key features is the machine's automated functionality, which allows for easy adjustment of laminating and cutting parameters. This feature eliminates the need for manual calibration, saving time and ensuring precise results. Additionally, the machine is equipped with sensors and detectors that can detect errors and prevent damage to the materials. This reduces waste and increases overall efficiency.

Another important feature is the built-in cutting capability. With this feature, laminated sheets can be precisely trimmed to the desired size and shape, eliminating the need for separate cutting equipment. This saves time and ensures uniformity in the finished products.

Furthermore, the 2-in-1 Automatic Vertical Laminating Machine has a user-friendly interface that makes it easy to operate and navigate. This feature allows for quick and efficient adjustments, minimizing downtime and maximizing productivity.

In summary, the key features of the 2-in-1 Automatic Vertical Laminating Machine contribute to enhancing production efficiency by simplifying operations, reducing manual labor, and ensuring consistent and high-quality laminated products.

Vertical laminating offers a range of advantages over traditional laminating methods. Firstly, vertical laminating eliminates the need for manual handling and reduces the risk of damage to laminated sheets. The 2-in-1 Automatic Vertical Laminating Machine allows for seamless feeding and exit of the materials, resulting in a smooth and efficient laminating process.

Additionally, vertical laminating saves time by combining the lamination and cutting processes into a single machine. With the built-in cutting capability of the 2-in-1 Automatic Vertical Laminating Machine, laminated sheets can be accurately trimmed to the desired size and shape, eliminating the need for separate cutting equipment. This reduces production time and ensures a consistent finished product.

Vertical laminating also offers enhanced productivity and cost efficiency. By automating the laminating and cutting processes, the 2-in-1 Automatic Vertical Laminating Machine streamlines operations and reduces the need for manual labor. This leads to increased productivity and cost savings for businesses.

Overall, vertical laminating improves efficiency in the production process, saves time and labor costs, and ensures consistent and high-quality laminated products. By utilizing this advanced technology, businesses can maximize their production efficiency and stay competitive in the market.

One of the key advantages of vertical laminating is its superior efficiency compared to traditional laminating methods. In traditional laminating, the process involves manual handling of laminated sheets, which increases the risk of damage and reduces productivity. However, with the 2-in-1 Automatic Vertical Laminating Machine, the need for manual handling is eliminated.

Traditional laminating methods also require separate equipment for cutting laminated sheets to the desired size and shape. This not only adds an additional step to the process but also increases the chances of inaccuracies and inconsistencies. On the contrary, the built-in cutting capability of the vertical laminating machine allows for precise and accurate trimming of laminated sheets, eliminating the need for separate cutting equipment and reducing production time.

Moreover, traditional laminating methods often require a significant amount of manual labor, leading to increased costs and potential human errors. By automating the laminating and cutting processes, the 2-in-1 Automatic Vertical Laminating Machine streamlines operations, reduces labor costs, and ensures consistent and high-quality laminated products.

Overall, the vertical laminating technology significantly improves efficiency and productivity compared to traditional laminating methods. It eliminates manual handling, combines laminating and cutting processes into a single machine, and reduces labor costs, making it a more cost-effective and efficient solution for businesses in various industries.

The 2-in-1 Automatic Vertical Laminating Machine offers significant efficiency and time-saving benefits compared to traditional laminating methods. By eliminating manual handling and combining the laminating and cutting processes into a single machine, it streamlines operations and maximizes production efficiency.

With traditional laminating methods, there is a risk of damage to laminated sheets during manual handling, leading to product wastage and reduced productivity. However, the vertical laminating machine eliminates this concern by automating the process, ensuring consistent and high-quality laminated products.

Moreover, having a built-in cutting capability saves time and reduces the need for separate cutting equipment. This not only eliminates additional steps in the process but also minimizes the chances of inaccuracies and inconsistencies.

By saving time and reducing the number of manual labor tasks, the 2-in-1 Automatic Vertical Laminating Machine ultimately reduces labor costs and increases overall productivity. Businesses in various industries, such as printing and packaging, food, cosmetics, and electronics, can benefit from this efficient and time-saving solution.

In conclusion, the vertical laminating technology offered by the 2-in-1 Automatic Vertical Laminating Machine significantly enhances efficiency, saves time, and improves productivity in various industries. It is a cost-effective and time-efficient solution for businesses aiming to maximize production efficiency.

Maintenance and Troubleshooting: The 2-in-1 Automatic Vertical Laminating Machine is designed with durability and reliability in mind. However, regular maintenance is essential to ensure optimal performance and extend the machine's lifespan.

To maintain the machine, it is important to follow the manufacturer's recommended maintenance schedule. This may include tasks such as cleaning the machine regularly, lubricating moving parts, and inspecting the electrical components for any signs of wear or damage.

Additionally, operators should be trained on proper machine operation and maintenance procedures to prevent any mishaps or damage. Regular training sessions and refresher courses can help ensure that operators are knowledgeable about the machine's maintenance requirements.

In the event of any issues or malfunctions, troubleshooting steps should be taken. These may include checking for loose connections, resetting the machine, or referring to the user manual for specific troubleshooting instructions. If the issue persists, it is best to contact the manufacturer or a qualified technician for assistance.

By adhering to a regular maintenance schedule and promptly addressing any troubleshooting needs, businesses can maximize the efficiency and longevity of the 2-in-1 Automatic Vertical Laminating Machine, ultimately optimizing their production processes.

To maximize the performance of the 2-in-1 Automatic Vertical Laminating Machine and ensure optimal production efficiency, there are several tips to keep in mind.

1. Regular Maintenance: Follow the manufacturer's recommended maintenance schedule to clean the machine regularly, lubricate moving parts, and inspect electrical components for any signs of wear or damage. This will help prevent unexpected breakdowns and keep the machine running smoothly.

2. Operator Training: Provide thorough training to operators on the proper operation and maintenance procedures of the machine. This will help minimize errors and prevent any mishaps that can lead to damage to the machine or decrease in production efficiency.

3. Correct Material Setup: Properly set up the materials being laminated in the machine. Ensure that they are aligned and placed correctly to avoid any issues during the laminating process.

4. Monitor Speed and Temperature: Adjust the laminating speed and temperature settings according to the materials being laminated. Monitoring these factors and making necessary adjustments will help achieve optimal lamination results and prevent any damage to the materials.

5. Regular Inspection: Conduct regular inspections of the machine to identify any potential issues or signs of wear. This will allow for timely repairs or replacements, preventing any major breakdowns and ensuring uninterrupted production.

By following these tips, businesses can optimize the performance of the 2-in-1 Automatic Vertical Laminating Machine, minimize downtime, and enhance overall production efficiency.

The 2-in-1 Automatic Vertical Laminating Machine is designed to maximize production efficiency, but like any complex machinery, it can encounter common issues. By being aware of these issues and understanding how to address them, businesses can minimize downtime and maintain optimal performance.

One common issue is material misalignment, which can lead to poor lamination results. To address this, operators should ensure that materials are properly set up and aligned before starting the lamination process. Regularly checking and adjusting the material alignment will help prevent any issues during operation.

Another common issue is machine jams. Jams can occur due to debris or improperly fed materials. Operators should regularly inspect the machine for any potential obstructions and clean the machine thoroughly. Additionally, they should ensure that materials are loaded correctly and fed smoothly into the machine, following the manufacturer's guidelines.

Electrical component malfunctions can also occur, leading to disruptions in production. It is important to regularly inspect electrical components for any signs of wear or damage. If any issues are identified, trained technicians should address them promptly.

By addressing these common issues proactively and ensuring regular maintenance, businesses can optimize the performance of the 2-in-1 Automatic Vertical Laminating Machine and maximize production efficiency.

In conclusion, the 2-in-1 Automatic Vertical Laminating Machine offers significant advantages in maximizing production efficiency. Its advanced functionalities and key features enhance the laminating process, reducing manual labor and saving time. The vertical laminating method proves to be more efficient and time-saving compared to traditional methods, making it a preferred choice for various industries.

The machine's versatility makes it suitable for applications in different sectors, such as printing and packaging, food, cosmetics, and electronics. It enables businesses to achieve high-quality lamination results, ensuring product durability and attractiveness.

To maintain optimal performance, regular maintenance is crucial. By following the manufacturer's guidelines and incorporating preventive measures, issues such as material misalignment and machine jams can be addressed effectively. Additionally, conducting regular inspections and prompt repair of electrical components will minimize downtime and disruptions in production.

Overall, the 2-in-1 Automatic Vertical Laminating Machine is a valuable asset for businesses seeking to optimize their production efficiency. As laminating technology continues to evolve, we can expect further advancements that will further enhance the performance and capabilities of these machines, enabling businesses to stay competitive in the market.

The 2-in-1 Automatic Vertical Laminating Machine has a significant impact on production efficiency. By incorporating advanced functionalities and key features, this machine streamlines the laminating process, reducing the need for manual labor and saving valuable time.

With its vertical laminating method, the machine offers enhanced efficiency compared to traditional laminating methods. The vertical orientation allows for faster and more seamless lamination, minimizing material misalignment and ensuring precise results. This results in increased productivity and faster turnaround times, ultimately boosting overall production efficiency.

The versatility of the 2-in-1 Automatic Vertical Laminating Machine also contributes to its impact on production efficiency. It can be utilized in various industries such as printing and packaging, food, cosmetics, and electronics, enabling businesses to achieve high-quality laminating results in different applications. This versatility eliminates the need for multiple machines, simplifying production processes and further optimizing efficiency.

To maximize the impact of the machine on production efficiency, proper maintenance and troubleshooting are crucial. Regular maintenance and prompt repair of any issues will minimize downtime and ensure uninterrupted production. By adhering to best practices and utilizing the machine's capabilities to their fullest extent, businesses can maximize their production efficiency and stay competitive in the market.

As technology continues to advance, the future of laminating technology holds exciting possibilities for further enhancing production efficiency. One key development in laminating technology is the integration of artificial intelligence (AI) and machine learning capabilities. This would enable the laminating machines to analyze data, adapt to specific materials and laminating requirements, and make real-time adjustments to optimize efficiency and quality.

Another area of future development is the use of advanced materials for laminating purposes. Researchers are exploring the use of new materials that offer improved performance, such as enhanced durability, heat resistance, and flexibility. These materials would enable laminating machines to handle a wider range of applications and withstand more rigorous production environments.

Furthermore, there is a growing focus on sustainability in laminating technology. The future will likely see the development of eco-friendly laminating machines that use biodegradable or recyclable laminating materials. This will help reduce the environmental impact of laminating processes and meet the increasing demand for sustainable solutions.

Overall, the future of laminating technology holds great potential for further improving production efficiency through the integration of AI, the use of advanced materials, and a focus on sustainability. By staying updated with these developments, businesses can stay ahead of the competition and continue to maximize their production efficiency.

Automatic Thermal Laminating Machine: Understanding Faults and Effective Solutions

2024-02-26Mastering the Art of Debugging: Tips for Optimizing Pre-Coating Laminating Machines

2024-02-19Automatic Pre-Coating Film Machines: Enhancing Convenience in Operations

2024-02-05Unveiling the Marvels: Characteristics and Applications of Vacuum Laminating Machines

2024-01-30EXPOGRÁFICA 2024 --12th-15th November Meet you in Mexico

2024-11-05Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01

26 Feb, 2024

READ MORE

Automatic thermal laminating machine can be divided into two categories: instant coating automatic thermal laminating machine and pre-coating automatic thermal laminating machine. It is a kind of special equipment for paper, board, and film laminating.

19 Feb, 2024

READ MORE

What are the tips for debugging the pre-coating laminating machine? The quality of the film is mainly the three factors of temperature, pressure, and speed, which are critical to the production of the following processes to ensure the quality of the pre-coated film.

05 Feb, 2024

READ MORE

It can also be found from the name of the automatic pre-coating film machine. The use of this equipment can achieve the advantage of automation, that is, it allows users to use less manual operations during use, which can also be reduced to a greater extent. Labor costs, so many users are also because of this, they will let themselves like to use this equipment, in addition to the above, this equipment also has its own differences in use.

30 Jan, 2024

READ MORE

Laminating machines can be divided into two categories: instant-coating laminating machines and pre-coating laminating machines. It is a kind of special equipment for paper, board, and film laminating. After being pressurized by rubber roller and heating roller, it is combined together to form a paper-plastic integrated product. Due to the wide application in daily life, today I will introduce the characteristics of the vacuum laminating machine.

05 Nov, 2024

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING