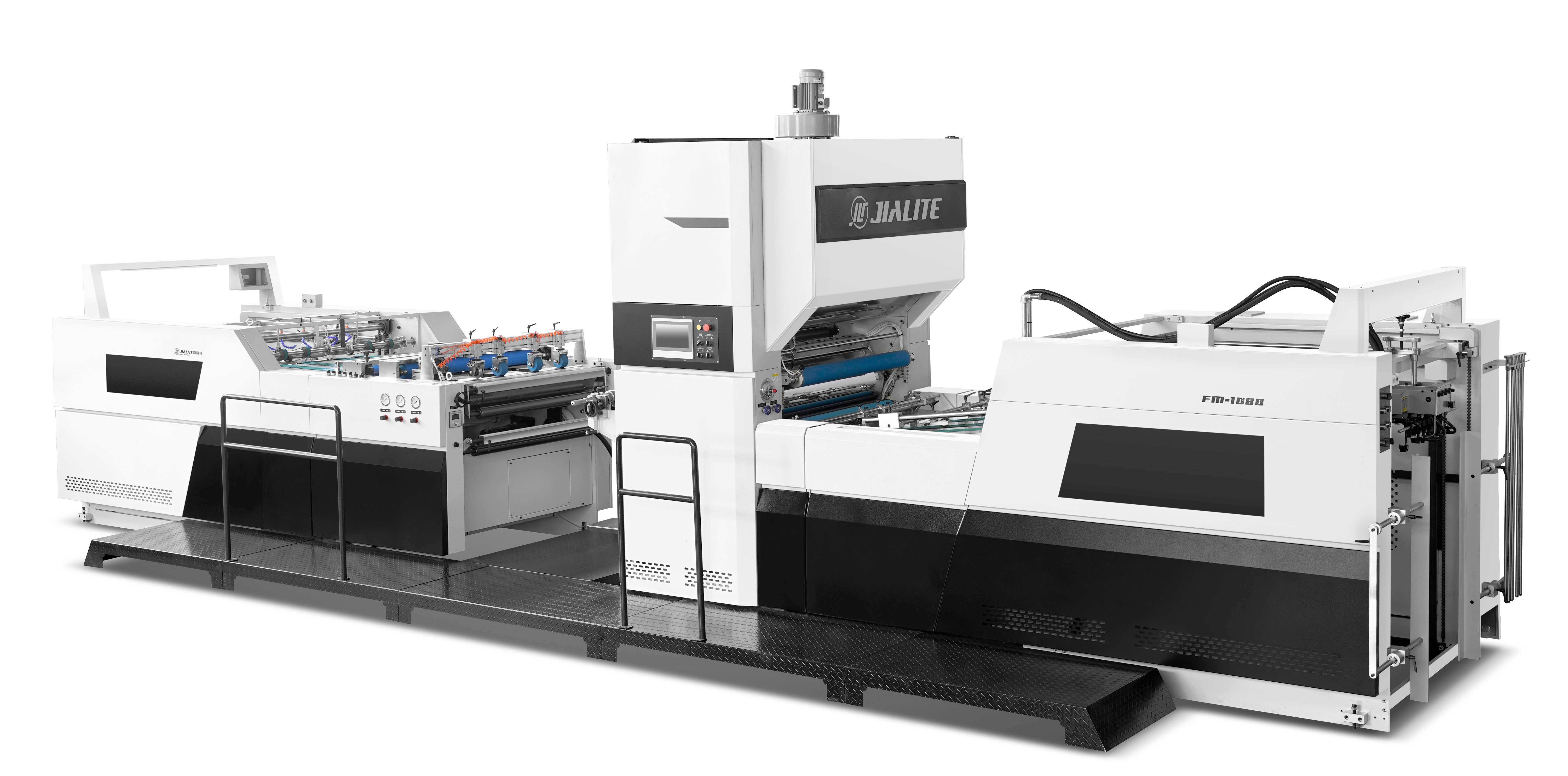

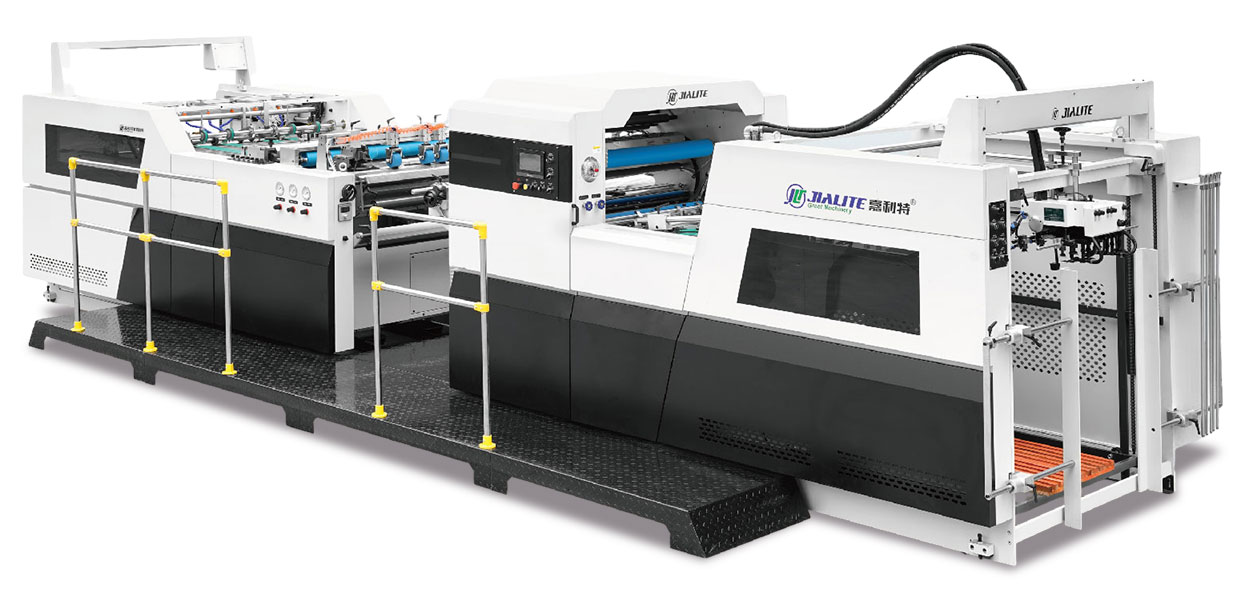

In the competitive world of luxury packaging, brands seek solutions that offer both aesthetic appeal and functional durability. Jialite's post-press equipment, including automatic laminating machines and UV oil coating machines, addresses these needs by providing high-quality finishes that enhance product presentation and protection.

Jialite's laminating machines support a variety of specialty films:

Sandy Film: Offers a textured, non-slip surface, ideal for packaging that requires a tactile experience.

Silk Film: Provides a smooth, lustrous finish, enhancing the visual appeal of luxury items.

Soft Touch Film: Delivers a velvety feel, adding a premium touch to packaging materials.

Metallic Film: Adds a reflective sheen, making products stand out on shelves.

PLA Films: Eco-friendly options that align with sustainable packaging initiatives.

These films enable brands to customize packaging aesthetics, catering to diverse consumer preferences.

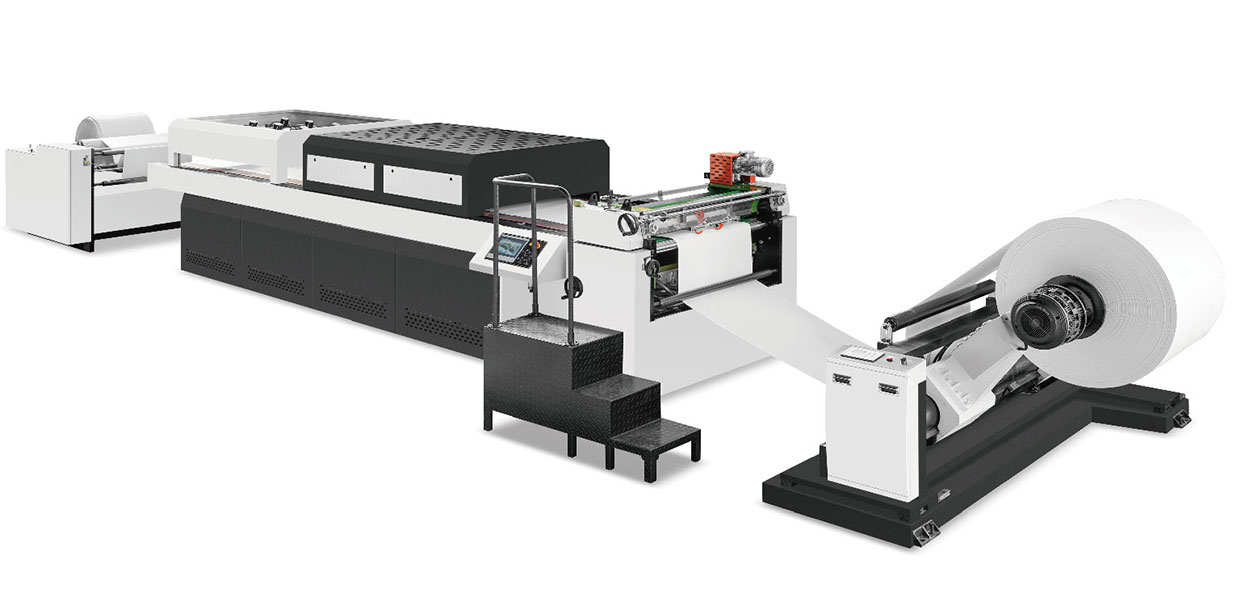

Jialite's automatic laminating machines are designed for precision and efficiency:

Advanced Temperature Control: Ensures consistent application across various materials.

Adjustable Pressure Settings: Accommodates different substrate thicknesses, preventing bubbles and wrinkles.

High-Speed Operation: Increases production rates without compromising quality.

User-Friendly Interface: Simplifies operation, reducing training time and errors

These features collectively enhance workflow efficiency, crucial for meeting tight production schedules.

The Automatic UV Oil Coating Machine applies protective layers that not only enhance visual appeal but also extend the lifespan of packaging materials:

Glossy and Matte Finishes: Cater to different branding requirements.

Scratch and Moisture Resistance: Protects packaging during handling and transportation.

Quick Drying Systems: Utilize infrared and ultraviolet technologies for rapid curing.

Consistent Application: Ensures uniform coating thickness, maintaining quality standards.

These capabilities are essential for luxury brands that prioritize both aesthetics and durability.

Jialite is committed to sustainability:

PLA Film Compatibility: Supports biodegradable materials, reducing environmental impact.

Energy-Efficient Machines: Designed to consume less power, lowering operational costs and carbon footprint.

Waste Reduction: Precision application minimizes material waste during production.

These initiatives align with global trends towards eco-friendly packaging solutions.

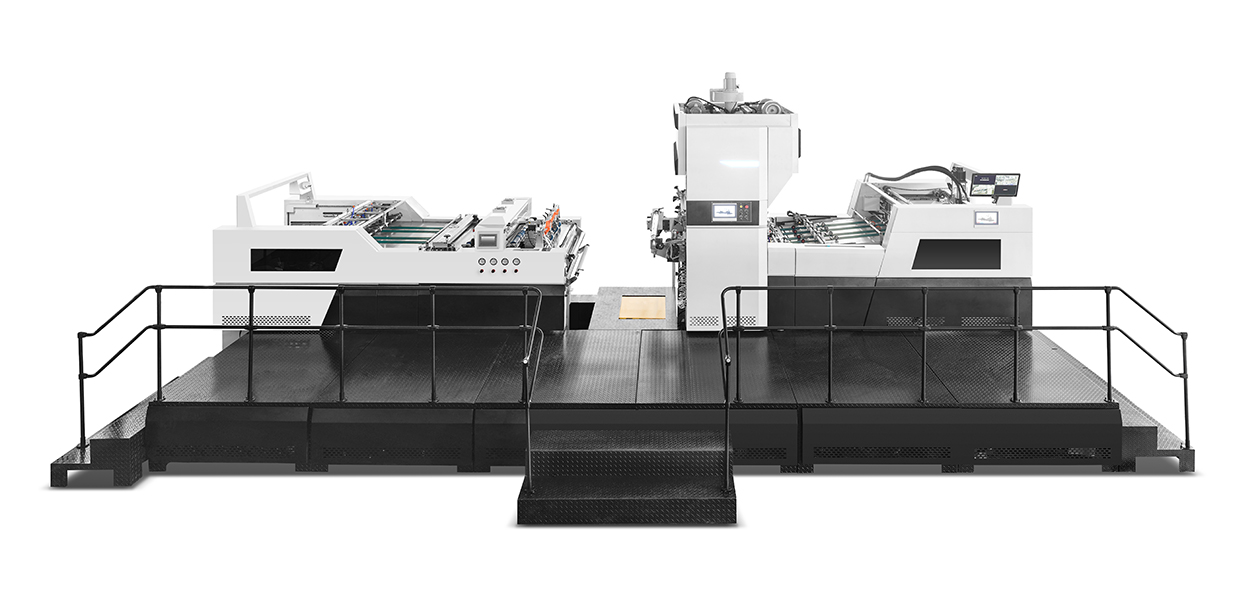

By integrating laminating and UV coating processes, Jialite offers a streamlined post-press solution:

Seamless Workflow: Reduces handling time between processes.

Consistent Quality: Maintains high standards across different finishing stages.

Space Optimization: Compact machine designs save valuable floor space.

Cost Efficiency: Combined functionalities lower investment and maintenance costs.

This holistic approach simplifies operations for manufacturers, enhancing overall productivity.

Jialite stands out in the post-press equipment industry for several reasons:

Innovative Technology: Continuous investment in R&D ensures cutting-edge solutions.

Customization: Machines can be tailored to specific production needs.

Global Support: Comprehensive after-sales service and technical assistance.

Proven Track Record: Trusted by leading brands in the luxury packaging sector.

These factors make Jialite a reliable partner for businesses aiming to enhance their packaging quality.

Q1: What types of materials can Jialite's laminating machines handle? A1: They are compatible with various substrates, including paper, cardboard, and biodegradable PLA films, accommodating different thicknesses and finishes.

Q2: How do specialty films enhance packaging?

A2: Specialty films like Sandy, Silk, and Soft Touch add unique textures and visual effects, elevating the unboxing experience and brand perception.

Q3: Are Jialite's machines energy-efficient?

A3: Yes, they are designed with energy-saving features, reducing power consumption and operational costs.

Q4: Can the UV Oil Coating Machine apply both glossy and matte finishes?

A4: Absolutely, it offers flexibility in finish types to meet diverse branding requirements.

Q5: Is it possible to integrate both laminating and UV coating processes?

A5: Yes, Jialite provides integrated solutions that combine both processes, streamlining production workflows.

Q6: Do the machines support high-volume production?

A6: They are built for scalability, handling large production volumes efficiently without compromising quality.

Q7: How does Jialite ensure consistent quality?

A7: Through precise control systems and advanced technology, ensuring uniform application and finish across all products.

Q8: Are the machines user-friendly?

A8: Yes, featuring intuitive interfaces and automated settings for ease of operation.

Q9: What support does Jialite offer post-purchase?

A9: Comprehensive after-sales service, including technical support and maintenance assistance.

Q10: Can Jialite's equipment be customized for specific needs?

A10: Yes, they offer customization options to align with unique production requirements.

Q1: How is sustainability influencing packaging choices?

A1: Brands are increasingly adopting eco-friendly materials and processes, like PLA films and energy-efficient machinery, to meet consumer demand for sustainable packaging.

Q2: What role does post-press equipment play in brand differentiation?

A2: High-quality finishes achieved through advanced laminating and coating enhance product appeal, setting brands apart in competitive markets.

Q3: How does automation impact production efficiency?

A3: Automated machines reduce manual intervention, increase consistency, and accelerate production timelines, leading to cost savings.

Q4: Why is customization important in packaging?

A4: Tailored packaging solutions meet specific brand aesthetics and functional requirements, enhancing customer engagement and satisfaction.

Elevate your packaging solutions with Jialite's advanced post-press equipment. For consultations, demonstrations, or more information, reach out to our team and discover how we can support your business's growth and innovation.

Zhejiang Hanyu to Showcase Smart Post-Printing Solutions at CHINA PRINT 2025

2025-04-30Which laminating machine brand in China is the best match for the German Koenig & Bauer offset press?

2025-02-19Elevate Surface Finishing with Jialite’s Precision Laminating Machines for Commercial Printing

2025-05-30Jialite Wide-Format Laminating Machines: Precision and Efficiency in Commercial Printing

2025-05-30Achieve Precision and Durability with Roll Paper Waterbase Oil Coating

2025-05-23Eco-Friendly UV Coating Solution: The SG-A for Packaging and Printing

2025-05-30Boost Productivity with the SG-AR1200 Automatic UV Varnishing Machine

2025-05-16Streamlining the Future of Packaging and Printing: The NFM-HP1080 Automatic Conveying Vertical Laminating Machine

2025-05-09Smarter Coating for Sustainable Paper Production

2025-04-30Flawless Finishing for Thin and Thick Paper – SG-E UV Varnisher

2025-04-25

30 Apr, 2025

READ MORE

19 Feb, 2025

READ MORE

JIALITE laminating machines are ideal for large-format printing with Koenig & Bauer presses. Offering superior quality, efficiency, and customizability, JIALITE ensures high-performance lamination for prints, enhancing durability and aesthetics.

30 May, 2025

READ MORE

This article explores the benefits of Jialite’s laminating machines in the commercial printing and packaging industry, highlighting their precision engineering, large-format capabilities, and advanced features that ensure superior surface finishing.

30 May, 2025

READ MORE

Jialite offers state-of-the-art wide-format laminating machines designed for the commercial printing and packaging industries. With features like precise tension control, advanced temperature regulation, and seamless integration with major printing systems, Jialite's laminators ensure high-quality finishes and operational efficiency.

23 May, 2025

READ MORE

The Roll Paper Waterbase Oil Coating Machine provides a high-speed, cost-effective solution for applying oil-based coatings to paper. Ideal for packaging and commercial printing, it offers precision, durability, and eco-friendly finishes that meet modern industry demands.

30 May, 2025

READ MORE

The SG-A Automatic UV Oil Coating Machine enhances printing and packaging processes with precision and efficiency. Ideal for high-volume jobs, it offers eco-friendly UV varnish solutions, delivering premium finishes while improving production speeds and reducing operational costs.

16 May, 2025

READ MORE

The SG-AR1200 Automatic Roll to Roll UV Oil Varnish Coating Machine offers precision, high-speed operation, and eco-friendly coating solutions for various industries. Perfect for enhancing product durability and finish quality while improving production efficiency.

09 May, 2025

READ MORE

The NFM-HP1080 automatic conveying vertical laminating machine offers high-precision lamination for various paper types. Its servo motor-controlled feeding and seamless integration with printing and die-cutting machines make it ideal for high-speed commercial printing and packaging.

30 Apr, 2025

READ MORE

Discover how the Roll Paper Waterbase Oil Coating Machine enhances paper durability and finish with eco-friendly, high-speed coating. Ideal for food packaging, publishing, and commercial printing, it improves quality, reduces waste, and boosts efficiency.

25 Apr, 2025

READ MORE

The SG-E UV oil varnishing machine combines automation, speed, and material versatility to support premium finishing across paper types from 80–600gsm. Ideal for commercial printers and packaging converters, it enhances quality and production efficiency.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING