In today's fiercely competitive market, businesses are incessantly seeking avenues to enhance the value proposition of their products, aiming to captivate customers and outshine rivals. UV coating technology has emerged as a pivotal instrument in this pursuit, bestowing an array of benefits that elevate the perceived value of products. This article delves into the multifaceted ways in which UV coating technology, particularly when harnessed through Automatic UV Oil Coating Machines, contributes to augmenting product added value.

UV coating technology embodies the application of ultraviolet (UV) light to expeditiously cure coatings and adhesives, engendering a resilient and lustrous finish on diverse substrates. Revered across industries for its prowess in enhancing aesthetics, durability, and tactile qualities, UV coatings serve as veritable game-changers in product enhancement endeavors. They impart a high-quality finish that heightens aesthetics, shields against wear and tear, and imbues products with a premium allure.

1. Exquisite Aesthetics: The foremost avenue through which UV coating technology enhances product added value lies in its ability to elevate aesthetics. The glossy finish conferred by UV coatings augments the visual allure of products, rendering them irresistibly appealing to consumers. Whether bedecking packaging materials, promotional paraphernalia, or printed materials, UV coatings elevate the perceived caliber of products and exude an air of professionalism.

2. Augmented Durability: Products ensconced in UV coatings evince augmented durability, evincing heightened resistance to scratches, abrasions, and fading. This heightened durability not only protracts product lifespan but also adds value by ensuring that they perpetuate their resplendence over time. Customers perceive products bedecked in UV coatings as imbued with superior quality and are predisposed to remunerate a premium for their durability.

3. Customization and Personalization: UV coating technology proffers avenues for customization and personalization, enabling businesses to engender unique and distinctive products. Facilitated by Automatic UV Oil Coating Machines, businesses can effortlessly bestow UV coatings upon an array of substrates, adjusting coating thickness and finish to satiate specific customer predilections. This faculty to tailor products to individual exigencies amplifies their perceived value and differentiation within the market milieu.

4. Brand Amplification: Investment in UV coating technology fortifies brand image and fosters a reputation for quality and innovation. Products embellished with UV coatings loom large on shelves, emanating an aura of sophistication and meticulousness. This felicitous association with quality engenders favorable impressions of the brand and cultivates customer loyalty and recurrent patronage.

5. Environmental Considerations: Beyond the realms of aesthetics and functionality, UV coating technology also dovetails with the burgeoning consumer predilection for eco-friendly products. UV coatings, bereft of solvents and characterized by minimal emissions of volatile organic compounds (VOCs), emerge as a more sustainable alternative vis-à-vis solvent-based coatings. By assimilating UV coatings into their products, businesses cater to the sensibilities of eco-conscious consumers, accentuating the perceived value of their offerings.

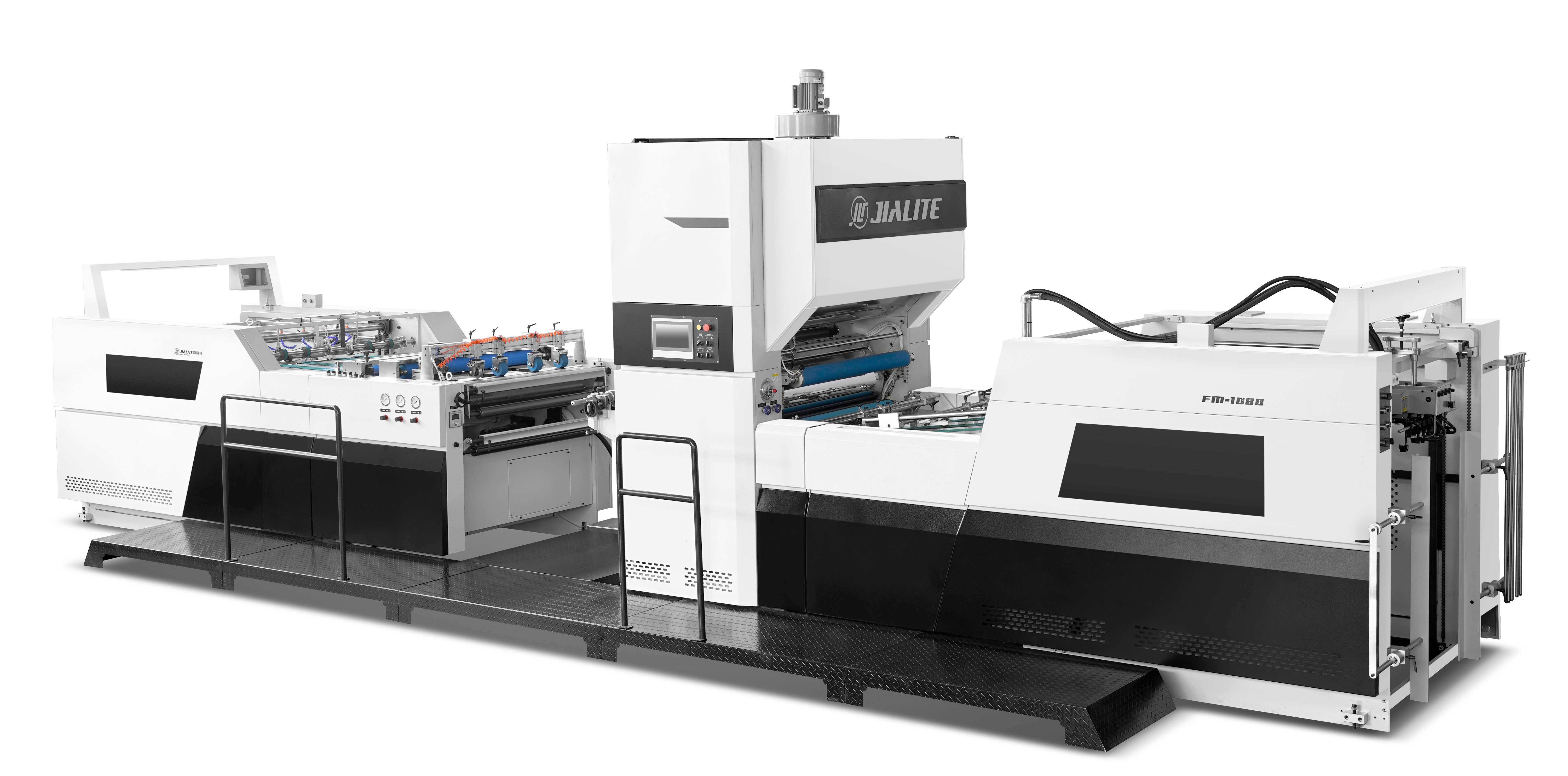

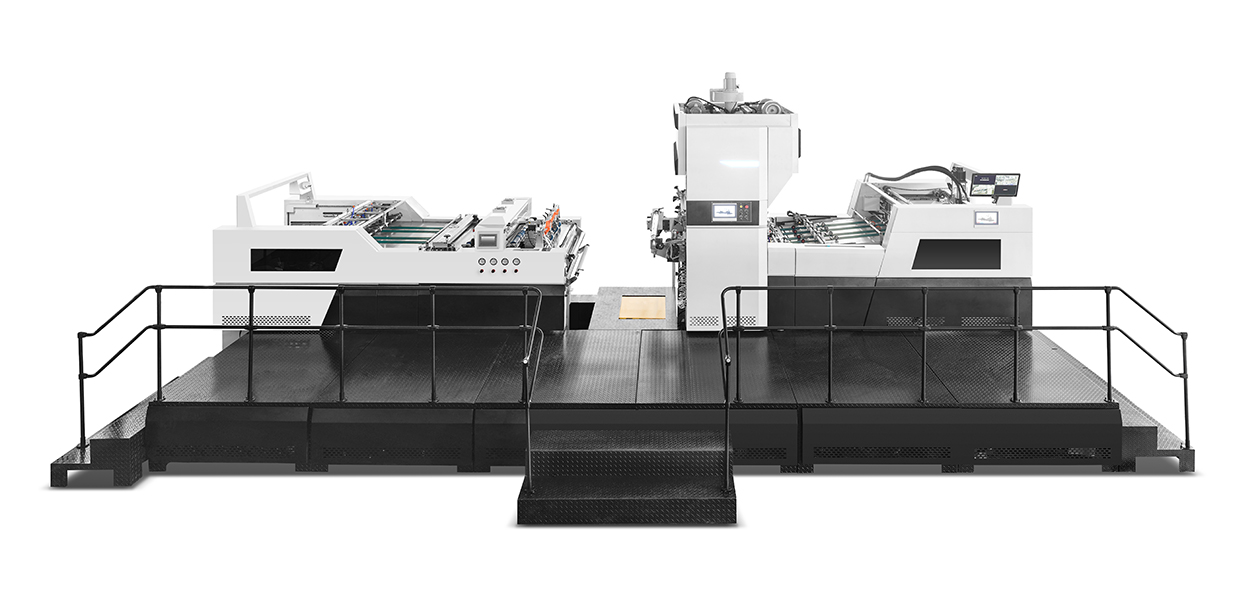

Automatic UV Oil Coating Machines assume an indispensable role in optimizing the benefits of UV coating technology and augmenting product added value. These cutting-edge contrivances proffer streamlined and uniform application of UV coatings, ensuring a superlative finish on each product. By automating the coating process, Automatic UV Oil Coating Machines truncate production time and labor costs, empowering businesses to scale their operations and cater to customer requisites with alacrity. Furthermore, these machines facilitate meticulous control over coating thickness and finish, enabling businesses to tailor products to precise specifications.

UV coating technology, when wielded through Automatic UV Oil Coating Machines, confers a panoply of benefits that elevate product added value. From ameliorated aesthetics and durability to customization and brand augmentation, UV coatings serve as conduits for fabricating high-caliber products that command premium prices in the market. By investing in UV coating technology, businesses can carve out a niche for themselves, fortify their brand image, and resonate with discerning consumers who venerate quality and innovation.

Why Choose JIALITE for Your Coating Machines?

2024-03-23Exploring Window Film Laminating Technology: Adding Convenience and Appeal to Your Products!

2024-04-11How UV Coating Technology Elevates Product Added Value

2024-06-06Exploring the Functions and Applications of Automatic Thermal Laminating Machines

2024-05-31EXPOGRÁFICA 2024 --12th-15th November Meet you in Mexico

2024-11-05Enhance Efficiency in Printing, Packaging, and Paper Processing with Jialite’s Varnishing & Laminating Machine Support

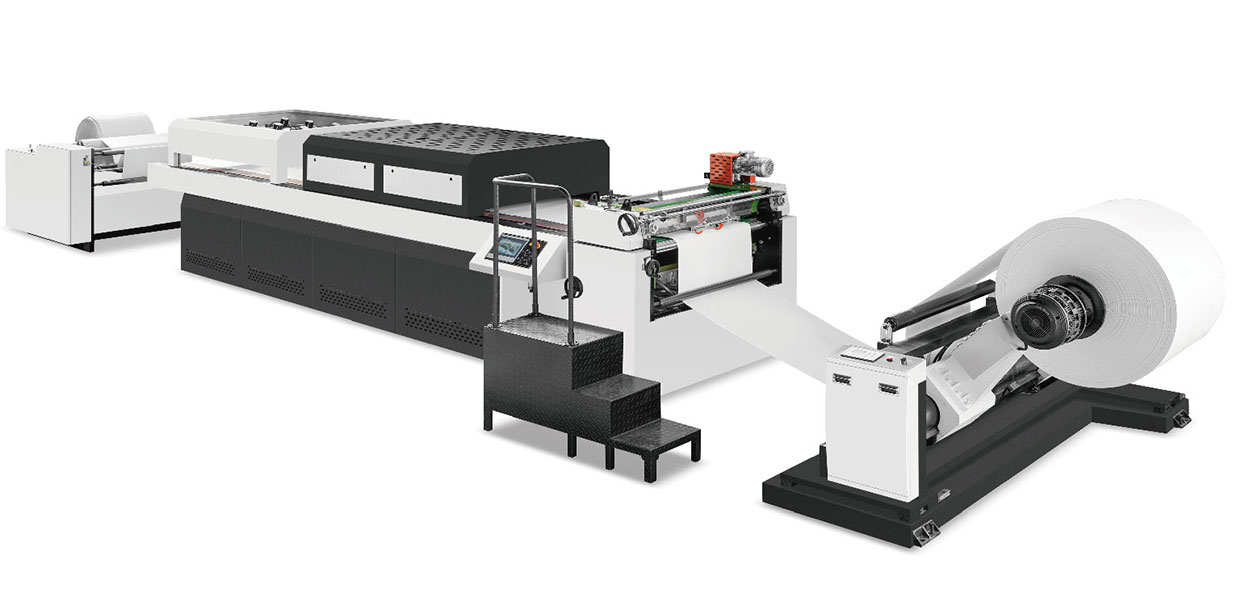

2024-11-01Optimize Production with the SG-AR1200 Automatic Roll-to-Roll UV Oil Varnish Coating Machine

2024-11-01

23 Mar, 2024

READ MORE

JIALITE is a trusted global leader in high-precision coating and laminating machines, offering cutting-edge solutions for printing, packaging, and paper processing industries. With decades of expertise, customized designs, and reliable support, JIALITE is your ideal partner for boosting production efficiency and quality.

11 Apr, 2024

READ MORE

Window film laminating technology not only provides an attractive display for products but also enhances consumer shopping experience and convenience. As an advanced packaging technique, it will continue to play a significant role in various industries, offering new possibilities and creativity in product packaging.

06 Jun, 2024

READ MORE

Explore how UV coating technology, including Automatic UV Oil Coating Machines, enhances product value through improved aesthetics, durability, and customization. Learn how businesses can leverage UV coatings to differentiate their offerings and appeal to eco-conscious consumers.

31 May, 2024

READ MORE

Explore the multifaceted functions and diverse applications of automatic thermal laminating machines. Learn how these advanced machines enhance productivity, efficiency, and quality across various industries, while also contributing to cost savings and environmental sustainability.

05 Nov, 2024

READ MORE

Differentiation creates value, and service moves customers; Garrett paper finishing technology makes printed matter a work of art, which is widely spread...

01 Nov, 2024

READ MORE

For the printing, packaging, and paper processing sectors, Jialite offers comprehensive installation, technical support, and operator training for varnishing and laminating machines. Our on-site services help companies in flexible packaging and corrugated carton production achieve seamless integration and maximum efficiency.

01 Nov, 2024

READ MORE

The SG-AR1200 by Jialite is an automatic roll-to-roll UV oil varnish coating machine designed for high-quality, durable coating applications. Ideal for packaging, printing, and corrugated carton manufacturing industries, this machine offers versatile oil compatibility and adjustable speeds, ensuring superior results.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING