In today's fast-paced commercial printing industry, the demand for high-quality, durable, and aesthetically pleasing printed materials is ever-increasing. Wide-format laminating machines play a crucial role in meeting these demands by providing protective finishes that enhance the longevity and appearance of printed products.

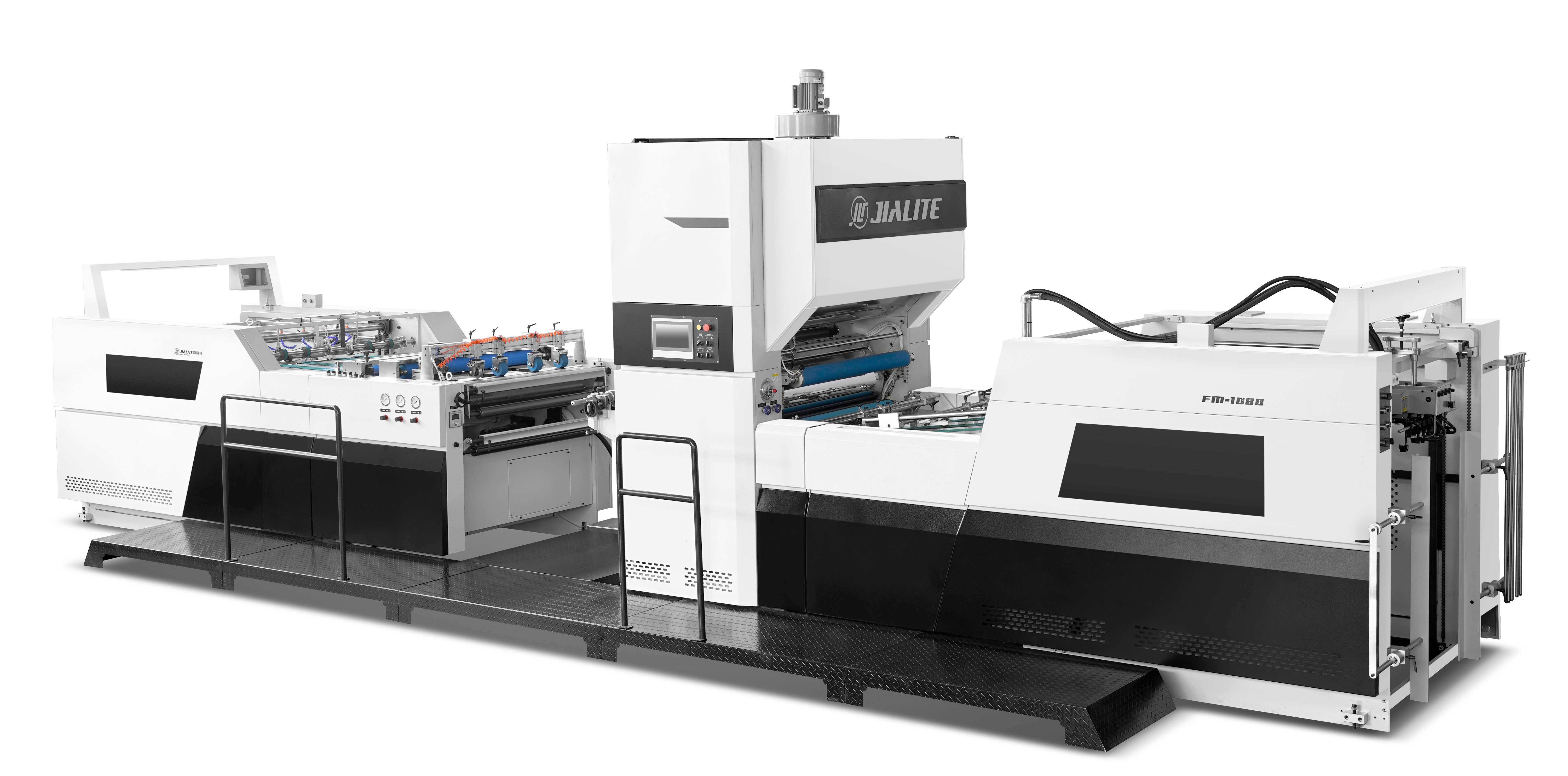

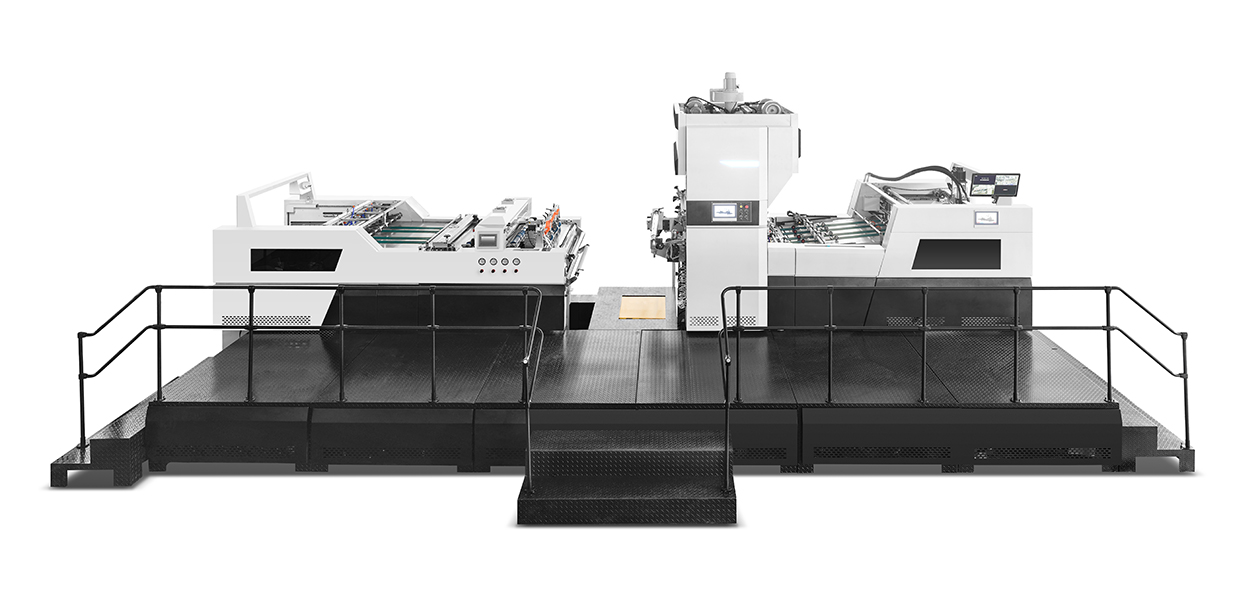

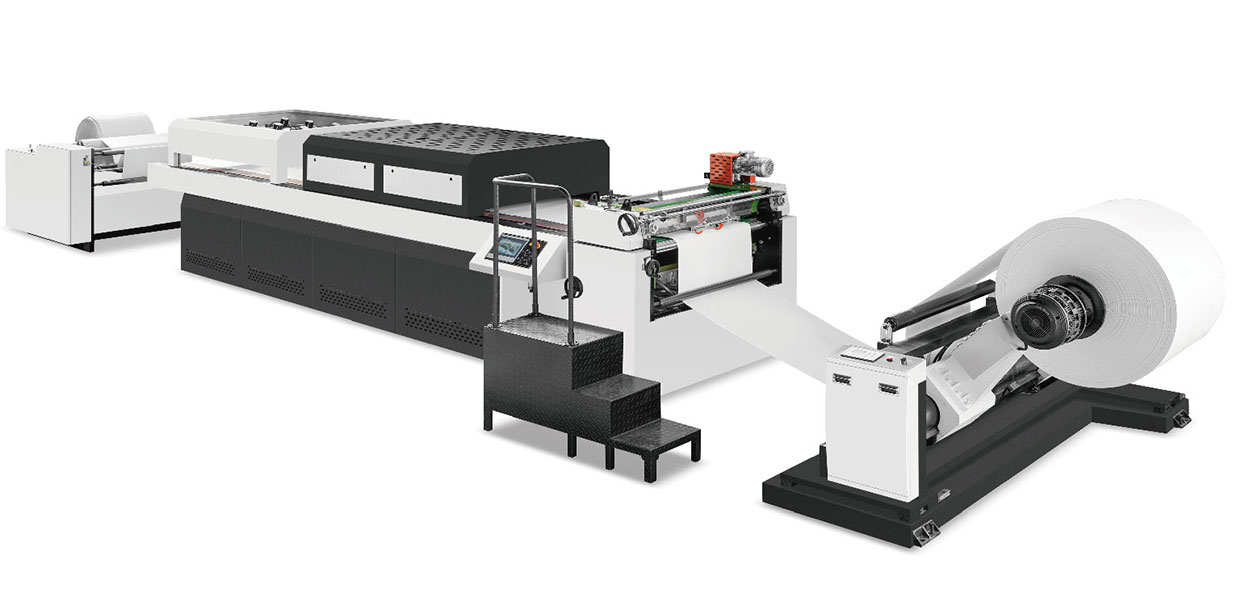

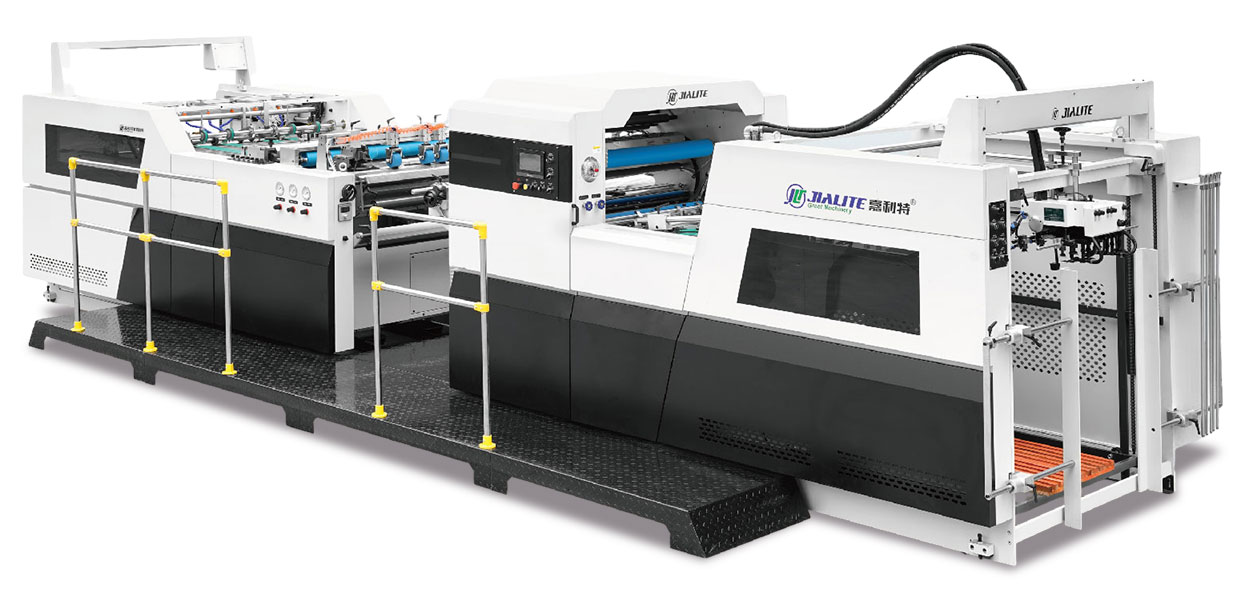

Jialite's wide-format laminators are engineered to handle large-scale projects efficiently, ensuring that businesses can meet tight deadlines without compromising on quality.

Jialite laminators are designed for high-speed operations, capable of processing up to 12,000 sheets per hour. This rapid throughput ensures that large orders are completed promptly, increasing overall productivity.

Maintaining consistent tension during lamination is vital to prevent issues like wrinkling or misalignment. Jialite's machines feature advanced tension control systems that ensure smooth and even lamination across all materials.

Different laminating films and substrates require specific temperature settings for optimal adhesion. Jialite's laminators come equipped with precise temperature control mechanisms, allowing for adjustments that cater to various materials, ensuring a perfect finish every time.

Understanding the importance of workflow efficiency, Jialite's laminators are designed to integrate seamlessly with major printing systems, including those from Koenig & Bauer. This compatibility ensures a streamlined production process, reducing downtime and manual interventions.

| Feature | Specification |

|---|---|

| Max Lamination Size | 1600 x 1850 mm |

| Speed | Up to 12,000 sheets/hour |

| Heating System | Electromagnetic with precise control |

| Tension Control | Advanced servo-driven system |

| Integration Compatibility | Koenig & Bauer and other major systems |

Jialite's laminating machines are versatile, catering to a wide range of applications:

Elevate your commercial printing and packaging capabilities with Jialite's state-of-the-art wide-format laminating machines. Contact us today to learn more about our products and how they can benefit your business.

Q1: What is the maximum lamination size Jialite machines can handle?

A1: Jialite's wide-format laminators can handle materials up to 1600 x 1850 mm, accommodating large-scale printing projects.

Q2: How do Jialite laminators ensure consistent lamination quality?

A2: Our machines feature advanced tension control and temperature regulation systems, ensuring even lamination without wrinkles or bubbles.

Q3: Are Jialite laminators compatible with other printing systems?

A3: Yes, Jialite laminators are designed to integrate seamlessly with major printing systems, including Koenig & Bauer, enhancing workflow efficiency.

Q4: What types of materials can be laminated using Jialite machines?

A4: Our laminators are versatile and can handle various materials, including paper, cardboard, and certain plastics, making them suitable for diverse applications.

Q5: Do Jialite machines support both hot and cold lamination?

A5: Yes, our machines are equipped to handle both hot and cold lamination processes, providing flexibility based on project requirements.

Q6: How user-friendly are Jialite laminating machines?

A6: Jialite laminators feature intuitive controls and interfaces, making them easy to operate, even for users with minimal technical experience.

Q7: What maintenance is required for Jialite laminators?

A7: Regular cleaning and periodic checks are recommended to ensure optimal performance. Our machines are designed for easy maintenance, with accessible components and clear guidelines.

Q8: Can Jialite laminators handle continuous operation?

A8: Absolutely. Our machines are built for durability and can operate continuously, making them ideal for high-volume production environments.

Q9: What safety features are included in Jialite laminators?

A9: Safety is a priority. Our machines come equipped with emergency stop buttons, protective covers, and sensors to ensure safe operation.

Q10: Where can I purchase Jialite laminating machines?

A10: You can contact our sales team directly or visit our official website for more information on purchasing options and authorized distributors.

In the evolving landscape of commercial printing, integrating advanced laminating solutions is essential for businesses aiming to deliver high-quality products efficiently. Wide-format laminators, like those offered by Jialite, not only protect printed materials but also enhance their visual appeal, making them more attractive to consumers.

Moreover, the ability to handle large volumes without compromising on quality ensures that businesses can meet tight deadlines and maintain customer satisfaction. Investing in reliable and efficient laminating equipment is a strategic move for any printing or packaging enterprise aiming for growth and excellence.

Zhejiang Hanyu to Showcase Smart Post-Printing Solutions at CHINA PRINT 2025

2025-04-30Which laminating machine brand in China is the best match for the German Koenig & Bauer offset press?

2025-02-19Eco-Friendly UV Coating Solution: The SG-A for Packaging and Printing

2025-05-30Achieve Precision and Durability with Roll Paper Waterbase Oil Coating

2025-05-23Boost Productivity with the SG-AR1200 Automatic UV Varnishing Machine

2025-05-16Streamlining the Future of Packaging and Printing: The NFM-HP1080 Automatic Conveying Vertical Laminating Machine

2025-05-09Smarter Coating for Sustainable Paper Production

2025-04-30Flawless Finishing for Thin and Thick Paper – SG-E UV Varnisher

2025-04-25Upgrade Your Post-Press Power with NFY-B1080 Automation

2025-04-18How to Choose the Right China Automatic Laminating Machine Equipment for Your Business

2025-04-10

30 Apr, 2025

READ MORE

19 Feb, 2025

READ MORE

JIALITE laminating machines are ideal for large-format printing with Koenig & Bauer presses. Offering superior quality, efficiency, and customizability, JIALITE ensures high-performance lamination for prints, enhancing durability and aesthetics.

30 May, 2025

READ MORE

The SG-A Automatic UV Oil Coating Machine enhances printing and packaging processes with precision and efficiency. Ideal for high-volume jobs, it offers eco-friendly UV varnish solutions, delivering premium finishes while improving production speeds and reducing operational costs.

23 May, 2025

READ MORE

The Roll Paper Waterbase Oil Coating Machine provides a high-speed, cost-effective solution for applying oil-based coatings to paper. Ideal for packaging and commercial printing, it offers precision, durability, and eco-friendly finishes that meet modern industry demands.

16 May, 2025

READ MORE

The SG-AR1200 Automatic Roll to Roll UV Oil Varnish Coating Machine offers precision, high-speed operation, and eco-friendly coating solutions for various industries. Perfect for enhancing product durability and finish quality while improving production efficiency.

09 May, 2025

READ MORE

The NFM-HP1080 automatic conveying vertical laminating machine offers high-precision lamination for various paper types. Its servo motor-controlled feeding and seamless integration with printing and die-cutting machines make it ideal for high-speed commercial printing and packaging.

30 Apr, 2025

READ MORE

Discover how the Roll Paper Waterbase Oil Coating Machine enhances paper durability and finish with eco-friendly, high-speed coating. Ideal for food packaging, publishing, and commercial printing, it improves quality, reduces waste, and boosts efficiency.

25 Apr, 2025

READ MORE

The SG-E UV oil varnishing machine combines automation, speed, and material versatility to support premium finishing across paper types from 80–600gsm. Ideal for commercial printers and packaging converters, it enhances quality and production efficiency.

18 Apr, 2025

READ MORE

Discover how the NFY-B1080 automatic thermal laminating machine empowers printers and packaging providers with speed, precision, and durability. Ideal for high-volume and short-run jobs, it delivers professional finishes and consistent quality.

10 Apr, 2025

READ MORE

This guide helps businesses select the right automatic laminating machine from China. It covers machine types, key technical features, application scenarios, and supplier evaluation tips.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING