Laminating Machine details maintenance method

The Laminating Machine has very high requirements for accuracy, especially the surface accuracy of each roller and the degree of shopping. Once the slightest streaks, cracks, scratches, covered spots, or slight roundabout deformations appear. Will affect the processing quality of the product, and even not work properly. Therefore, it is very important to protect the machine carefully and carefully.

Protection and maintenance of the machine

1.Frequently check the oil pipes, valves and cylinder plugs of the hydraulic system for oil leakage. When oil leakage is found, the sealing ring should be replaced in time, and an appropriate amount of hydraulic oil should be filled into the hydraulic cylinder in time.

2. Frequently check whether there is rubber or grease on the rubber roller, and clean the rubber and dust on the roller in time. Ensure that the surfaces of the two rolls are clean and dark. The surface of each roller must be kept clean. After each application of the machine, be sure to clean the machine immediately.

Use glue thinner to wash and wipe each roller with a soft towel. It is strictly forbidden to scrape the surface of the roller with a sharp tool. Every time the machine is turned on, the dust on the surface of each roller should be wiped off. And check whether the surface of each roller of the machine is dark, if the machine is malfunctioning or abnormal sound, you should analyze and find the cause in time and clear it. The machine can be used only after the standby device is normal.

3. The grounding of the machine and the insulation of electrical appliances should be ensured well.

4. The blade line of the squeegee should be kept flat and elastic. When there is a roundabout, tooth gap, curling, etc., it should be trimmed and replaced in time. The manganese steel skin of 0.15~0.20 mm or the blade of the offset printing machine should be used according to the original specifications. Change the size.

5. Lubricate the transmission parts and sliding surfaces of the Automatic Laminating Machine regularly to ensure that the machine is in a good lubrication state. Especially the large bearing of the pressing roller encounters high pressure and high temperature, and the lubricating oil volatizes and loses casually. The high-temperature lubricating oil should be dwarfed in time to make it work normally under high temperature and high pressure.

6. The machine must be inspected once a year to find and solve problems in time to avoid more serious damage to the machine.

JIALITE is one of the top Water Base Oil Coating Machine Manufacturers, Factory and Suppliers that focuses on Automatic pre-coating laminating machine. We have our own production workshop and design team. If you cooperate with us, we can provide you with first-hand prices.

Welcome to choose JIALITE - one of the top Water Base Oil Coating Machine Manufacturers, Factory and Suppliers that focuses on Automatic pre-coating laminating machine.

For more product information about YouTube and Automatic coating machine, you can click on the relevant link below.

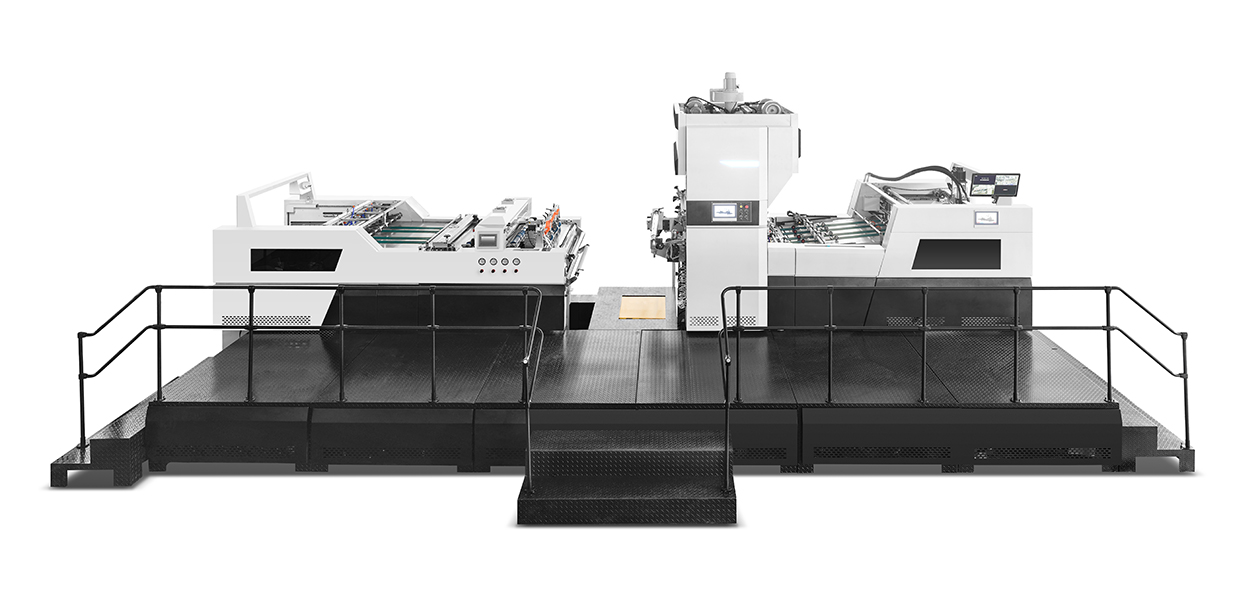

AUTOMATIC VERTICAL LAMINATING MACHINE 2 IN 1

SG-E Automatic Thin and Thick Paper UV Oil Varnishing Machine

NFM-HP1080 Automatic Conveying Vertical Laminating Machine

How to choose Automatic coating machine manufacturers

2022-01-18How to use the Laminating Machine

2022-02-28Care and maintenance of coating machine

2022-02-21Automatic coating machine working principle use application

2022-02-08

18 Jan, 2022

READ MORE

Due to the lack of in-depth understanding, most friends do not know which part of Automatic coating machine manufacturers to choose to obtain satisfactory results. In fact, as long as we have the patience to explore more things, we will soon know that manufacturers that have been established for many years, while focusing on the industry, have cooperated with different customers, and they will definitely have strong strength.

28 Feb, 2022

READ MORE

The Automatic Laminating Machine is a special equipment for compounding printed matter with pre-coated plastic. Compared with the instant coating type laminating machine, its biggest feature is that there is no glue coating and drying part, so this type of laminating machine has compact structure, small size, low cost, simple operation and good product quality stability.

21 Feb, 2022

READ MORE

Ensure that the coating equipment is installed horizontally. It should be grounded, and an independent leakage switch should be installed for safe use.

08 Feb, 2022

READ MORE

The auto coater consists of a control system, a hot air filtering system, coating pan, solution tank, and exhaust system. The film to be coated on the tablet is in liquid form before the process is started so the liquid is filled in the solution tank. The liquid is stirred well in the solution tank and then pumped into the coating pan. The coating pan is perforated and holds a batch of tablets that are to be coated.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING