Industrial Laminator Machine User Guide

Industrial Laminator Machine User Guide

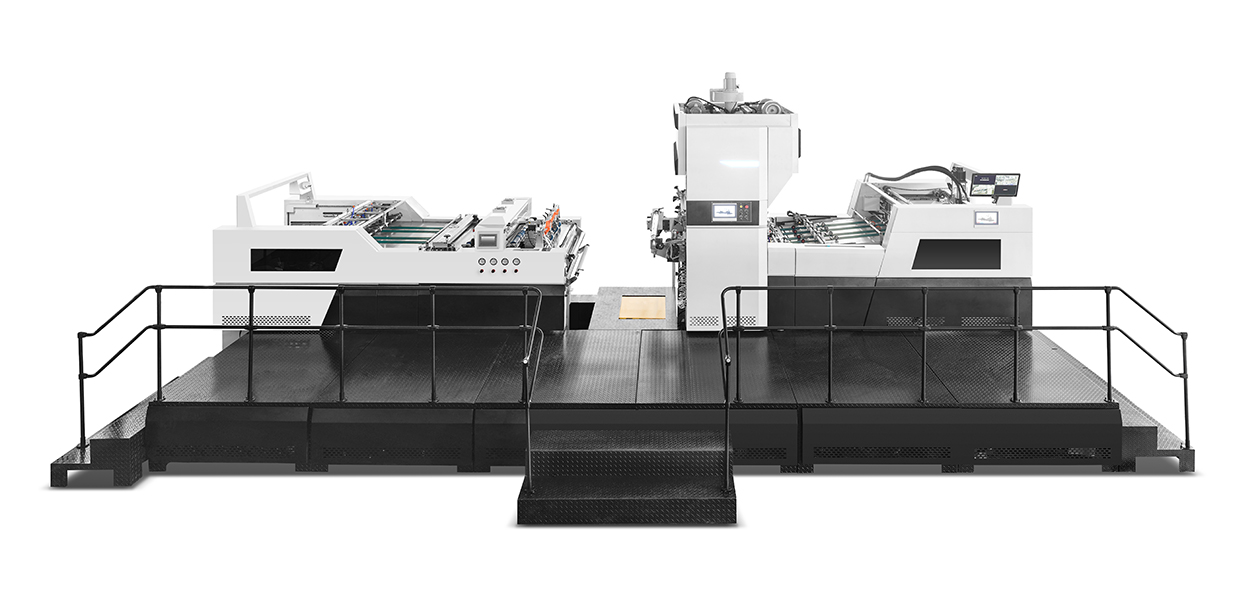

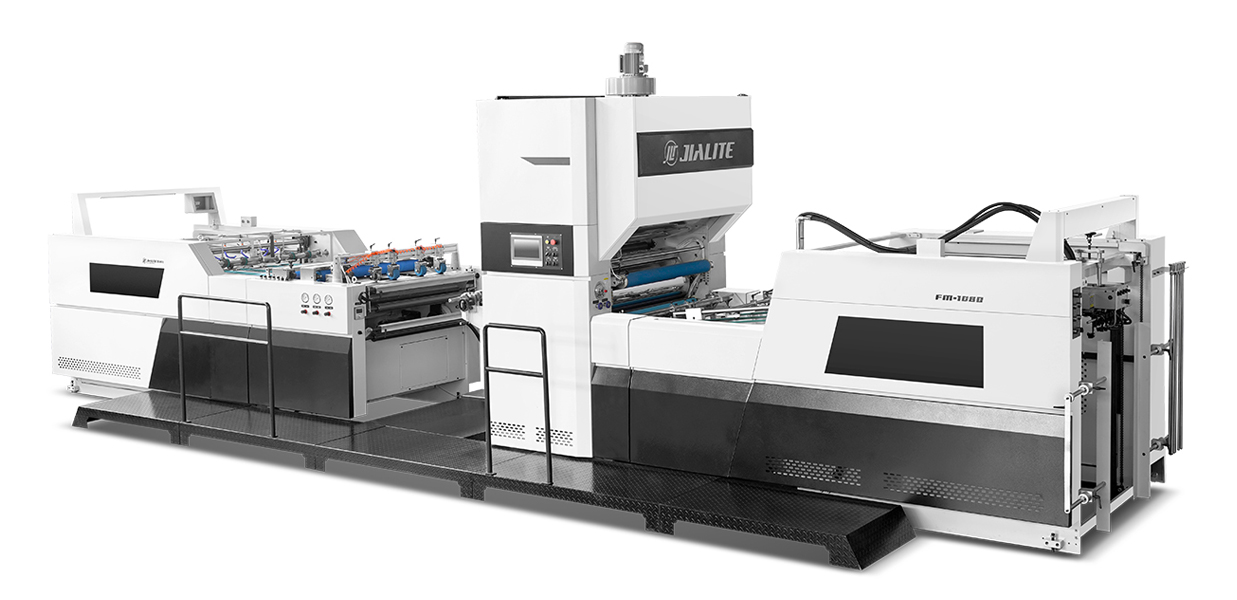

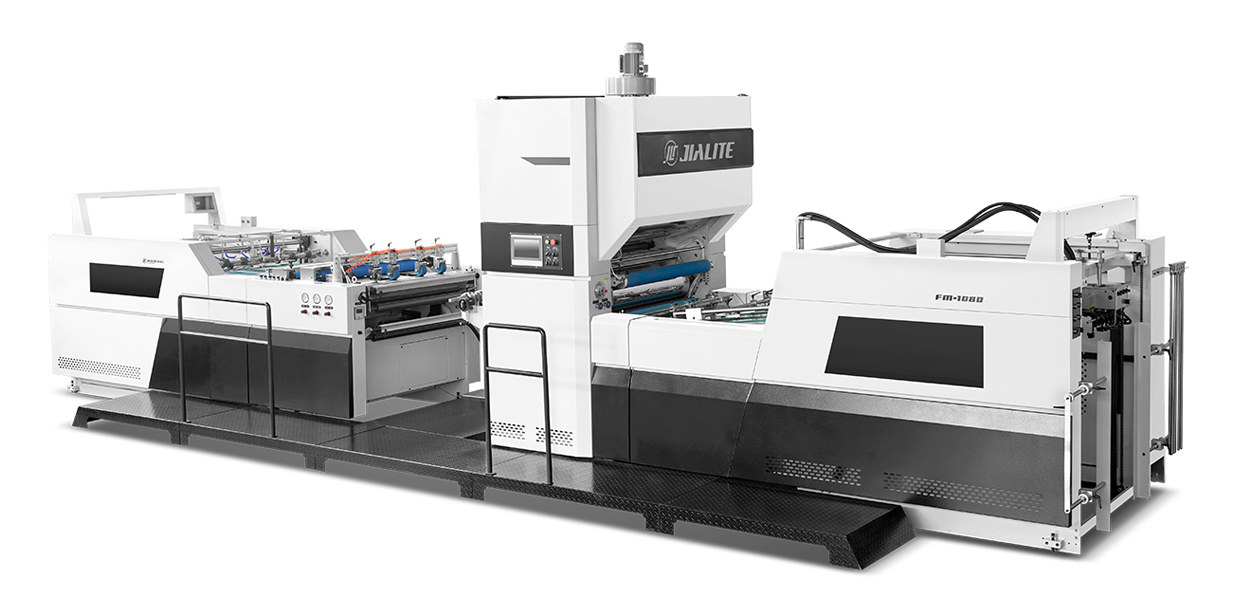

An industrial laminator is a machine that is used to laminate documents and other materials. Laminating is a process in which a thin layer of plastic is applied to the surface of a document in order to protect it from damage. Industrial laminators are different from home laminators in that they are much larger and more powerful. They are also designed for heavy-duty use and can handle large quantities of material at once.

If you are thinking about purchasing an industrial laminator, there are a few things you should keep in mind. First, you need to decide what size machine you need. Industrial laminators come in a variety of sizes, so you need to make sure you get one that is big enough to handle the amount of material you will be working with. Second, you need to decide what features you want. Some industrial laminators have built-in cutting machines, while others do not. You will also want to consider the speed at which the machine can laminate documents. The faster the better! Finally, you need to consider the price.

The industrial laminator machine is a versatile and powerful tool that can be used in a variety of settings. Here are some tips on how to use it effectively:

-Read the user guide carefully before operating the machine.

-Be sure to set the correct temperature and pressure settings for the materials you are working with.

-Use protective gloves and eyewear when working with the machine.

-Clean the machine regularly to prevent buildup of adhesive residue.

An industrial laminating machine is a device that is used to apply a thin layer of plastic film to surfaces such as paper, cardboard, or fabric. This process is known as lamination. Laminating machines are commonly used in offices and schools to protect documents from wear and tear, as well as to make them more resistant to fading from sunlight or moisture.

When choosing an industrial laminating machine, it is important to consider the size and type of documents that you will be laminated. It is also important to consider the speed at which you need the job done. For example, if you need to laminate a large number of documents quickly, you will need a machine that can handle high volume jobs.

Precautions for Industrial Laminator Machine

The laminator machine is a big help for those who are working in the industrial sector. It is very useful for the workers to have this machine in their workstation. With the help of this machine, they can easily laminate the products that they are working on. This will help to protect the products from getting damaged.

Regular cleaning of your laminator is important to ensure optimal performance and prevent jams. Additionally, taking some basic precautions will help to prolong the life of your machine. Here are a few tips:

-Never use solvents or abrasives to clean the laminator.

-Only use laminate pouches that are the correct size for your machine.

-Be sure to use the correct settings for your pouch thickness.

-Do not overlaminate.

-Do not leave the laminator on for extended periods of time without using it.

-Be sure to unplug the laminator when it is not in use.

- Always wear proper safety gear when operating the machine.

- Read the manual carefully before use and follow all instructions.

- Never leave the machine running unattended.

- Keep children and pets away from the machine while in operation.

What is the price of industrial roll laminator machine

When it comes to industrial roll laminator machines, the price tag can vary greatly. Depending on the size of the machine and its usage, industrial roll laminator machines can range from a few hundred dollars to several thousand dollars. Some factors that may push up the cost include speed and if additional rollers are available.

For those looking for a quick and inexpensive industrial roll laminator machine, there are plenty of basic options out there. However, it's important to make sure you get one that meets your particular needs in order to get your money's worth.