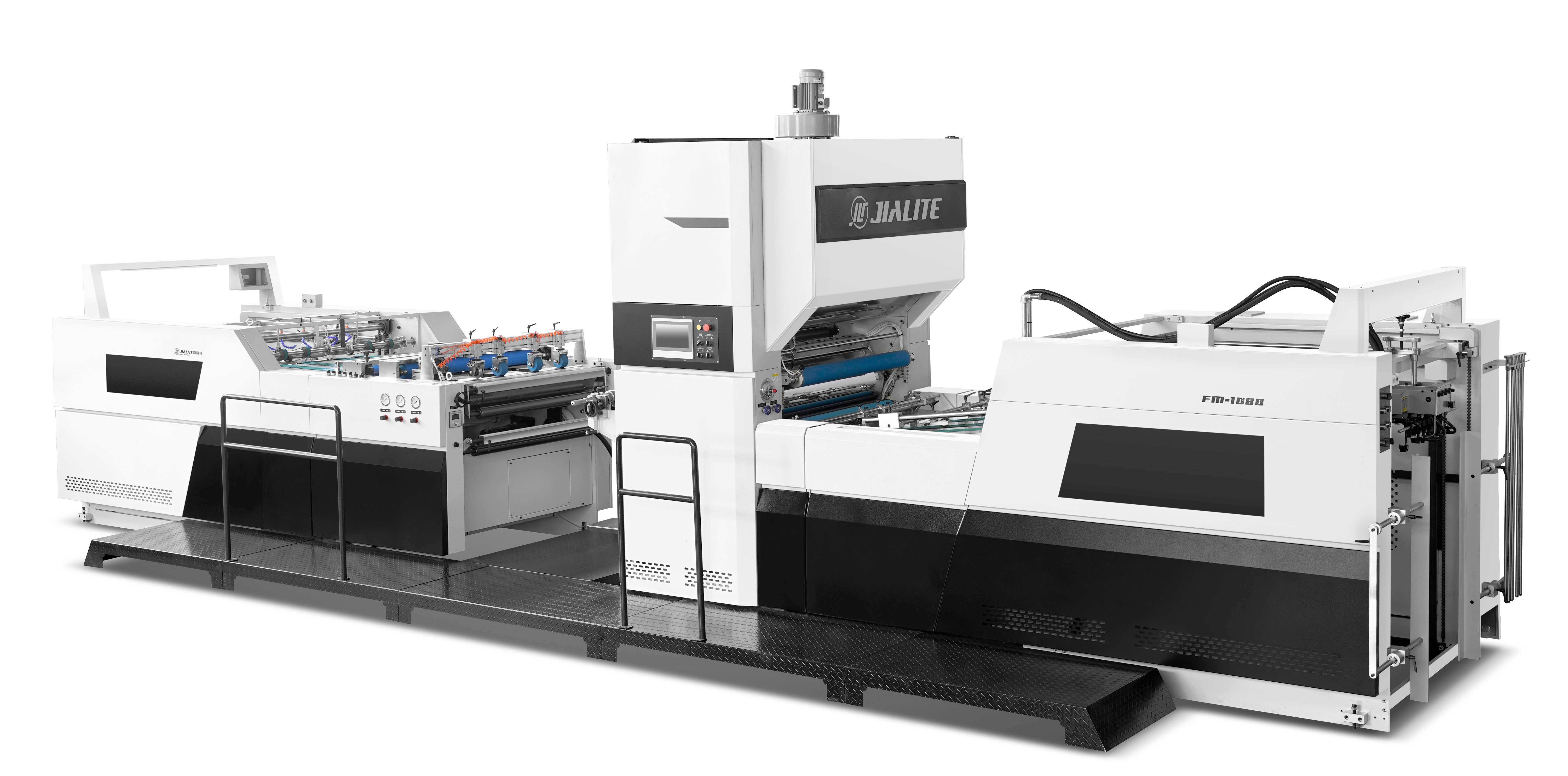

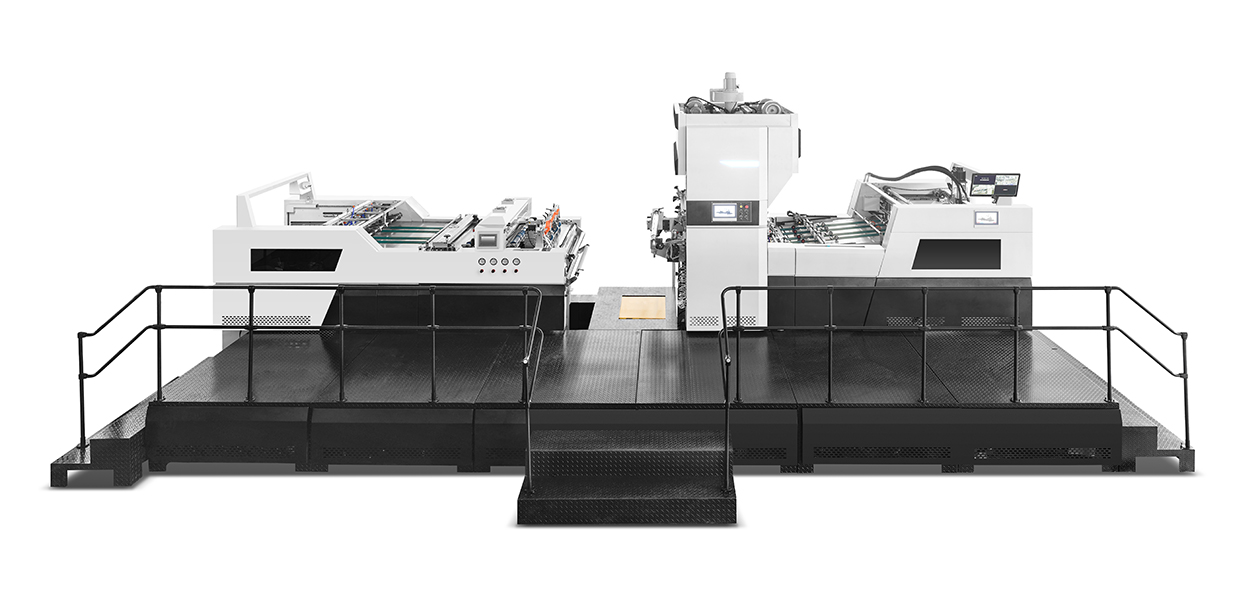

The NFM-E1080 dual-purpose laminating machine supports both water-based glue and thermal film lamination.

Water-based glue lamination is recyclable and ideal for food-grade and eco-packaging applications.

Thermal film lamination delivers faster throughput and lower cost for commercial print runs.

Changeover between lamination modes can be completed in under 15 minutes with minimal tools.

The machine accommodates sheet sizes up to 1080 mm with adjustable nip pressure.

It features an anti-curl bar, automatic sheet separation, and PLC-based automation for consistent quality.

Power consumption is optimized for both lamination modes to balance cost and sustainability.

Delivery to Southeast Asia can be completed in 30–35 days; CE and ISO certifications are included.

The machine offers strong ROI by reducing labor, improving uptime, and meeting eco mandates.

JIALITE provides full on-site installation, training, and global after-sales support.

Sustainability is no longer optional in packaging and printing. Printing houses must meet eco targets while delivering premium finishes at commercial speed. The JIALITE NFM-E1080 dual-purpose laminator solves this challenge by combining water-based glue and thermal film lamination in one high-performance system.

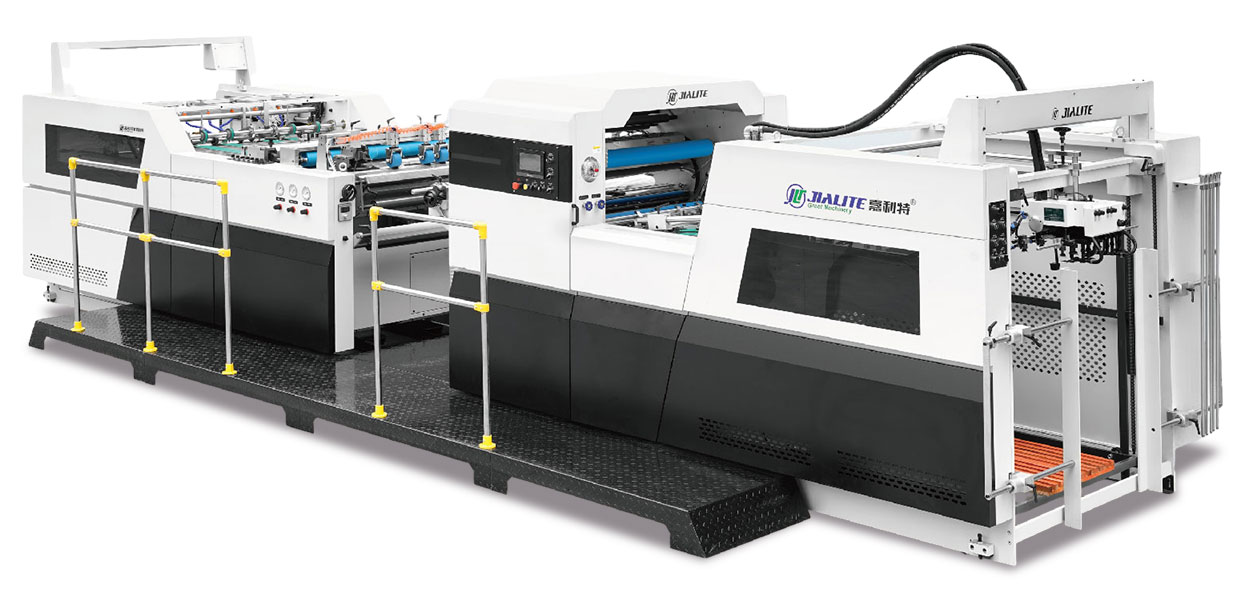

Water-based glue lamination is recyclable, odor-free, and ideal for food-grade or eco-sensitive packaging. The NFM-E1080 ensures even glue application, fast drying, and wrinkle-free surfaces, producing cartons and publications that meet environmental standards.

What are the benefits of water-based glue lamination?

It’s recyclable, food-safe, and compliant with strict eco regulations.

What is the glue consumption rate?

Typical usage is 2–3 g/m² depending on paper stock and film.

How to maintain the glue system?

Daily cleaning prevents clogging; an automatic wash cycle is standard.

Topic: Water-Based Glue Lamination

Key Insight: Eco-friendly lamination option meeting food-grade and sustainability goals.

Max Sheet Size: 1080 mm width

Speed: 60–80 m/min (water-based mode)

Certifications: CE, ISO

Glue System: Automatic application and cleaning

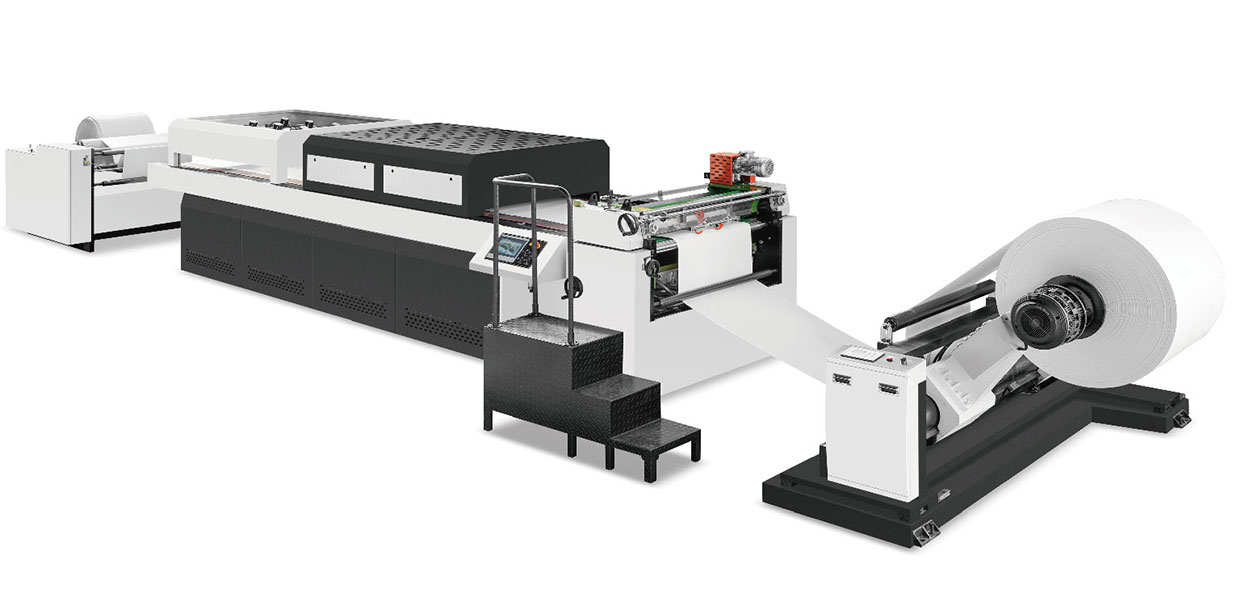

Thermal film lamination uses pre-coated film and heated rollers for fast, cost-efficient output. It’s ideal for books, magazines, and high-volume commercial print jobs.

Which jobs are best suited for thermal lamination?

Large runs with standard print finishes where speed is critical.

How fast is the NFM-E1080 in thermal mode?

Up to 90–100 m/min on coated stocks.

How to handle air bubbles during lamination?

Adjust nip pressure and pre-heat film rollers; the anti-curl bar reduces defects.

Topic: Thermal Film Lamination

Key Insight: Fast throughput for commercial applications.

Speed: 90–100 m/min (thermal mode)

Power Consumption: 28 kW typical

Certifications: CE, ISO

Anti-Curl: Included

Switching between water-based and thermal lamination is straightforward on the NFM-E1080. Operators can change lamination mode in under 15 minutes, maximizing machine uptime.

What makes a dual-purpose laminator better for varied jobs?

It eliminates the need for two machines and reduces floor space.

How does changeover compare to dedicated machines?

Changeover is tool-free and completed in under 15 minutes.

What is the ROI of investing in this system?

Most users achieve full ROI in 18–24 months due to labor and equipment savings.

Topic: Dual-Purpose Flexibility

Key Insight: One machine covers both eco and commercial lamination needs.

Changeover Time: <15 minutes

Labor Savings: Up to 50% vs manual laminators

PLC Control: Siemens-based

| Machine Type | Max Speed | Lamination Modes | Changeover Time | Eco Rating | Avg. Cost (USD) |

|---|---|---|---|---|---|

| Dedicated Water-Based Glue | 60–80 m/min | Water-based only | N/A | Very High | 80,000–100,000 |

| Dedicated Thermal Film | 90–110 m/min | Thermal film only | N/A | Medium | 70,000–90,000 |

| NFM-E1080 Dual-Purpose | 60–100 m/min | Water-based & Thermal | <15 min | High | 95,000–125,000 |

Product Name: JIALITE NFM-E1080 Dual-Purpose Laminating Machine

Lamination Modes: Water-based glue & pre-coated thermal film

Max Sheet Size: 1080 mm

Speed: 60–80 m/min (water-based), 90–100 m/min (thermal)

Changeover Time: <15 minutes

Power: 28 kW typical (thermal)

Certifications: CE, ISO

Lead Time: 30–35 days (Southeast Asia delivery)

Key Benefit: Combines eco-packaging compliance with high-volume productivity

Website URL: https://www.jltlaminating.com/article/nfm-e1080-dual-purpose-laminating-machine

Q: What is the maximum sheet size for the NFM-E1080?

A: The machine handles sheets up to 1080 mm wide.

Q: How does the NFM-E1080 compare in changeover speed?

A: Changeover between lamination modes is completed in under 15 minutes, faster than most competitors.

Q: Which substrates can it process?

A: Coated and uncoated paperboards from 100–500 gsm.

Q: What certifications are available?

A: CE and ISO certifications are included for export markets.

Q: Does it include anti-curl and sheet separation features?

A: Yes, both are standard for defect-free output.

Q: What is the typical ROI?

A: Most customers recover the investment within 18–24 months.

Q: Can JIALITE provide on-site training?

A: Yes, full installation and training are included with purchase.

Automatic laminating machine maintenance (anchor: laminator maintenance guide)

Water-based vs thermal lamination (anchor: lamination process comparison)

Eco-friendly packaging finishes (anchor: eco-packaging laminating options)

Laminator ROI calculator (anchor: dual-purpose laminator ROI)

Fogra

ISO

Packaging Europe

UL Solutions

REACH Helpdesk

Last updated: February 6, 2025

Author: Chief Product Engineer, JIALITE Laminating Systems

Reviewers: Compliance Lead; QA Lead

Zhejiang Hanyu to Showcase Smart Post-Printing Solutions at CHINA PRINT 2025

2025-04-30Which laminating machine brand in China is the best match for the German Koenig & Bauer offset press?

2025-02-19Automatic Color Box Making: Lamination & Varnishing Are Key to Premium Finishes

2025-07-31UV Coating’s Eco-Friendly Evolution Is Redefining Premium Packaging

2025-07-30Fully Automatic Laminating Machines for Decorative Paper Products – Complete Guide (2025)

2025-07-30Large-Format Sheetfed Lamination – Technology, Applications & Equipment (2025 Edition)

2025-07-30Beyond Expectations: Performance and Reliability of the HanYu SG-E1200 Automatic UV Varnisher

2025-07-25Hanyu NFM-HP1080 Automatic Vertical Laminating Machine: Precision, Reliability, Versatility

2025-07-17Unleashing Premium Quality with JIALITE’s Automatic Laminating and UV Coating Machines

2025-07-10Precision and Plush: Mastering Packaging with Soft Touch Laminating Films and Hanyu's Technology

2025-07-03

30 Apr, 2025

READ MORE

19 Feb, 2025

READ MORE

JIALITE laminating machines are ideal for large-format printing with Koenig & Bauer presses. Offering superior quality, efficiency, and customizability, JIALITE ensures high-performance lamination for prints, enhancing durability and aesthetics.

31 Jul, 2025

READ MORE

Lamination and UV varnishing are essential to achieve premium finishes in automatic color box making lines. These processes add durability, gloss, and visual impact while protecting print quality. JIALITE’s laminating and varnishing machines integrate seamlessly with folding, die cutting, and gluing equipment, enabling complete automated box production solutions with consistent high-quality output.

30 Jul, 2025

READ MORE

Eco-friendly UV coatings and automatic UV oil coating machines are transforming premium packaging by offering recyclable, low-VOC finishes that comply with environmental regulations. Modern machines, like JIALITE’s, feature modular designs, high speeds, and flexible switching between water- and oil-based coatings, ensuring premium quality, reduced VOC emissions, and long-term ROI for packaging lines.

30 Jul, 2025

READ MORE

Fully automatic laminating machines improve durability, moisture resistance, and visual impact for decorative paper goods. Water-based and thermal processes cover outdoor and premium finishes. JIALITE’s NFM-E1080 and NFY-B offer dual-mode or pre-coat thermal options, servo register control, inline slitting, safety compliance, remote diagnostics, and custom widths/voltages to maximize speed, quality, and ROI.

30 Jul, 2025

READ MORE

Large‑format sheetfed lamination adds durability, aesthetics, and functionality to oversized prints (B1 and larger). Automatic vertical type laminating machines—exemplified by JIALITE—offer compact footprints, high sheet‑per‑hour throughput, servo precision, thermal or cold processes, inline options (stackers, pre‑coat), safety compliance, and OEM customization for packaging, signage, and premium graphics.

25 Jul, 2025

READ MORE

This article introduces the HanYu SG-E1200 Automatic UV Varnisher, highlighting its revolutionary capability to deliver flawless varnishing results regardless of paper thickness. It delves into its cutting-edge memory-based PLC-controlled air knife system, impressive speed, broad application versatility, and the trusted reliability synonymous with the HanYu brand, making it an indispensable asset for enhancing print quality and productivity.

17 Jul, 2025

READ MORE

This article delves into the core strengths of the Hanyu NFM-HP1080 Automatic Vertical Laminating Machine, highlighting its unwavering consistency in output quality, engineered reliability for continuous operation, and exceptional versatility through its modular design and optional configurations. It emphasizes how these attributes collectively contribute to superior product quality and a more efficient, adaptable production workflow.

10 Jul, 2025

READ MORE

This article delves into how JIALITE’s Automatic Laminating and UV Coating Machines are the ideal solution for businesses in packaging, printing, and advertising looking to boost their holiday marketing. It explores how these advanced machines produce premium-quality, visually striking, and durable promotional materials, enhancing texture, appeal, and resilience during the bustling festive season.

03 Jul, 2025

READ MORE

This comprehensive article explores the transformative power of Soft Touch Laminating Films for premium packaging, emphasizing their luxurious feel and protective qualities. It highlights how Hanyu's Fully Automatic Laminating Machine is engineered to perfectly integrate these films, ensuring precision, efficiency, and exceptional results for high-end applications across various industries.

THE LEADER OF PACKAGING MACHINERY

CONTACT USPHARMACEUTICAL PACKAGING