HIGH SPEED AUTOMATIC THERMAL LAMINATING MACHINE

NFY-B

Automatic Double Side Laminating Machine - USAGE:

FY series pre-coat glue automatic thermal laminating machine as a professional equipment used for plastic film laminating on the surface of paper printed matter. Improving the printing matter grades, and achieve the purpose of dust-proof, waterproof, oil proof.

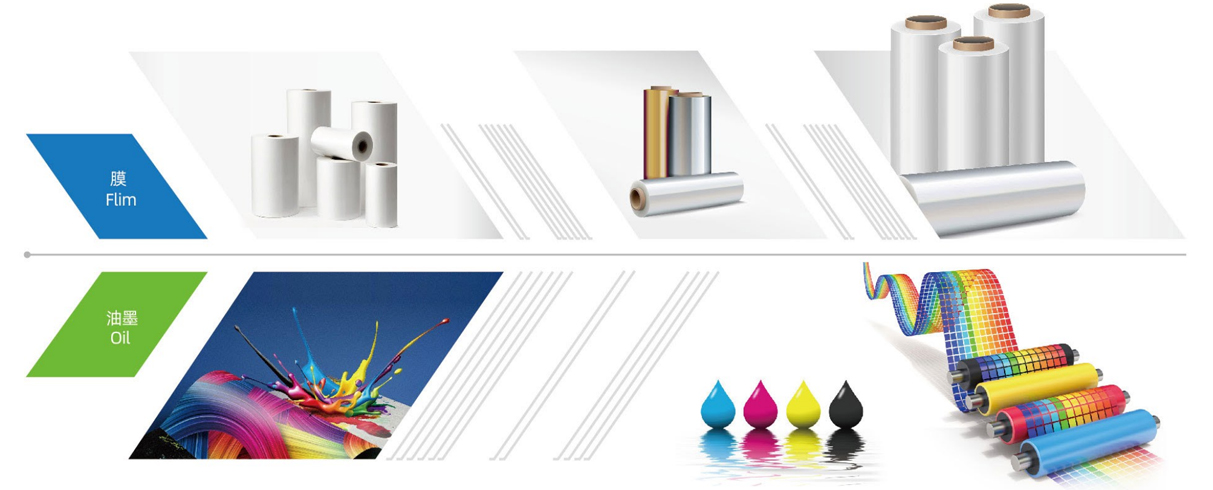

F Thermal laminating (Pre-coated /thermal film)

F Film: OPP, BOPP, SOFT TOUCH FILM.

Internet of things remote auxiliary control system, data generation and management to create perfect conditions for sustainable production.

1. Automatic Double Side Laminating Machine - FEEDER

Feeder adopts separate servo drive and shaftless drive.

High-performance suction head, valve for reliable sheet separation.

For maximum production speeds across the entire range of materials from 80-500gms, 12000 times/min.

Extremely flat feeder table for minimal material stress, matching with the paper press holder is used to assist the smooth delivery of paper to the host machine.

Main and auxiliary stack lifting conversion device, non-stop feeding.

2.Automatic Double Side Laminating Machine - THERMAL LAMINATING UNIT

Heating roll with Chromium treatment, Electromagnetic heating system, Temperature sensor inner, Intelligent constant temperature system.

Side gauge, overlap controlled by servo motor, accuracy ≤±2mm.

Rubber pressure roll automatic pressurization;

Paper miss detection, Automatic lubrication & cooling.

The main control touch screen is installed on the host to control the functions of the host and perform additional operations on other units, which is time-saving, intuitive and ergonomic, improved working environment, Maximum user-friendliness.

The round knife is suitable for BOPP/OPP film laminating. Cutting unit with a thin paper anti roll device and a quick paper breaking device assisted by a bouncing roller to ensure the flat lamination of the thin paper.Punching knife is commond standard.

3. Automatic Double Side Laminating Machine - NON STOP COLLECTOR

Non-stop paper collectting, exchange the paper catching board by manual.

Non stop paper collecting device, no need insert the wood board which catch the paper pile by manual, reduce the labor intensity.

4. Automatic Double Side Laminating Machine - OTHER OPTIONAL DEVICE

Modular control system with targeted adaptation to the customer’s wishes.

FUNCTIONAL REQUIREMENTS

Inkjet print and laminating.

Automatic Double Side Laminating Machine

China JIALITE is one of the leading Automatic pre-coating laminating machine, Water Base Oil Coating Machine, automatic coating machine Manufacturers, Factory and Suppliers. If you cooperate with us, we can provide you with first-hand prices.

No matter from which point of view, we are the best choice. Welcome to choose JIALITE - is one of the leading Automatic pre-coating laminating machine, Water Base Oil Coating Machine, automatic coating machine Manufacturers, Factory and Suppliers. >>>More products

This means that we are a company with a long history, but at the same time, we can use the most advanced technology and innovative business ideas to help determine the future trend of the industry. JIALITE's mission is to shape the digital future of our industry.

Automatic Metal Material Laminating Machine Manufacturers - Fully automatic laminating machine and varnishing machine as professional paper surface decoration equipment, suitable for hardcover gift box packaging, cardboard color box packaging, tag cards, advertising posters, picture books and magazines, information books, calendars, calendars, and other fields to improve products Ideal choice for printing companies, color printing and packaging companies, graphic printing, and post-press processing centers.

Automatic Metal Material Laminating Machine Manufacturers JIALITE is a reliable and highly innovative laminating machine partner for the global printing industry. The laminating machine produced by JIALITE is not only reliable in quality, but also superior in performance. At the same time, it has perfect after-sales service to ensure every customer's due rights.

Automatic Laminating Machine Manufacturers JIALITE plays a leading technical role through integrated solutions and new digital business models. Solutions, we focus on the end-to-end digitization of customer value creation systems, especially integrated system solutions for machines, software, consumer products and performance services.

With our technological leadership in our core business and our focus on digitalization, we are responding to the global market. Experts predict that this market will achieve moderate growth in the next few years, thanks to our products and services. A solid foundation, thanks to its annual printing output exceeding its investment in packaging, advertising and label printing.

We are also committed to new markets outside the printing industry. For example, with our expertise in the field of power electronics, we have successfully established our position in the electric vehicle market. Our printing technology also allows us to enter the production field of printed organic electronic products, which is a future market with huge potential.